ABS Plastic Vs. Polycarbonate Plastic: What’s the Difference?

If you read our blog regularly, you already know what polycarbonate plastic is. Today we’re going to focus more on ABS plastic and the difference between these two.

Acrylonitrile Butadiene Styrene aka ABS is a thermoplastic material that is made out of these three materials which are used widely in housing, electronic, and pipe fittings materials. ABS is also a high impact resistant material that can be sometimes used as an alternative to polycarbonate. However, the strength, flexibility, transparency, and impact resistance of polycarbonate is much higher than abs.

Maybe, you want to know the difference between Polypropylene Vs Polycarbonate.

Head To Head Comparison

Today you’re going to learn the key differences between these two and will be able to decide while shopping for plastic. All you have to do is read the entire guide and let us know the feedback at the end. So, let’s begin…

Basic Comparison

Polycarbonate is a robust and extremely impact-resistant thermoplastic material, which enables it to be suitable for applications that require higher strength. If you don’t know it, please see this blog “what is polycarbonate sheet“.

ABS is a blend of three types of material and often used for forming various shapes and glossy finishing. It also offers great impact resistance but not equal to PC materials.

Transparency

Polycarbonate is a transparent material that offers extremely well transparency while providing great light transmission too. On the other hand, ABS is an opaque material.

Applications

If you’re reading this, chances are you’re considering buying any one of these for an application. Let’s see which one is better for what in a nutshell.

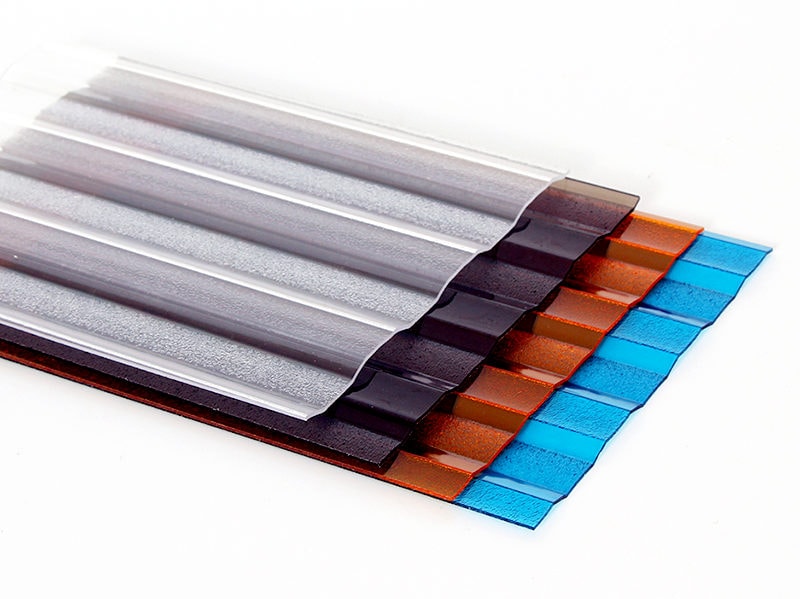

Polycarbonate is a UV-resistant and transparent material that can be used as an alternative to both glass and metal products, which allows it to be a great choice for windows and roofing panel. It also offers a great light transmission. The weather-resistant ability makes it even more suitable for windows and roofing panels in extreme weather condition prone areas.

ABS has an impact-resistant ability too, but when compared to the other alternative, the strength is significantly low. Generally, it doesn’t have a UV-resistant ability. It’s an opaque material, so it doesn’t provide light transmission either.

However, abs don’t have a wide range of applications. It’s often used in computer keyboards, electrical components, lego bricks, auto parts, etc.

Polycarbonate can be used for glamping dome, riot shield, large aquariums, walls, and many other areas where the highest strength is an absolute necessity.

Abs plastic offers high impact resistant, but when it comes to the application. It can’t withstand the impact like PC plastic does. This is why the application of this plastic is limited to small components and luggage, briefcase, etc.

Here, you need to know some information about machining polycarbonate.

Both the materials are fairly flame resistant. However, abs have a low melting point which is sometimes a disadvantage. On the other hand, polycarbonate offers a fair deal of flame resistance and a higher melting point. When comparing these two plastics, we have to mention the differences between them in luggage and briefcases. A lot of people get confused between these two materials.

We have a separate guide for you about the primary differences between polycarbonate luggage and abs luggage. Feel free to visit that if you want a detailed guide. However, we’ll talk about this here as well, but briefly.

Related Blogs

Luggage and Briefcase

Both materials are widely used and extremely favorite for luggage products. Both offer excellent looks and value for the user. But there are some vital differences between these two.

When you have a low budget and need hardshell luggage, and don’t require a long lifespan, you can comfortably go with an abs luggage. They offer great looks and strength for luggage and you can get a sweet deal on a low budget. However, the durability and lifespan of your luggage won’t be too long and it can break with high impacts if not used softly.

On the other hand, polycarbonate luggage is virtually unbreakable and offers ultimate strength for the users. The longer lifespan and durability make them favorite among frequent travelers. Although the price of this luggage is a bit high, the longer lifespan makes them the winner overall.

Cost

Abs plastic is the most economical and affordable than the other. The material is designed to provide great value with less cost.

Polycarbonate material is usually more expensive than abs and acrylic plastic. But offers more strength and durability. If you need plastic for a long-term project. This will still be the best choice for you.

Which one is better?

The goal of this article was to highlight the key differences and abilities of these two materials. Not to declare a winner.

By now, you already know polycarbonate is more impact resistant, higher strength, and durable material that can withstand any harsh weather conditions.

On the other hand, abs also offer great value at a low cost for the user. This plastic material is a great choice for luggage and briefcases. At an affordable price, you could get nice-looking luggage for your next tour.

Which one is the best for you?

As you can see both the options have some advantages and disadvantages. You have to choose one according to your requirements.

Using abs plastic for greenhouses doesn’t make sense. And using polycarbonate for lego bricks isn’t a great decision either.

You have to pick your material considering why you need it for.

Conclusion

That’s it for today! Now that you know the differences, pick the right one for your needs. And if you’re still unsure, ask your question in the chatbox and we’ll help you right away.

By the way, don’t forget to share this simple guide with your friends and family. So the next time they go shopping for plastic, they don’t have to rely blindly on the shopkeeper to make their decision.

Related Articles

About UVPASTIC

UVPLASTIC is a leading manufacturer of polycarbonate in China. Meantime, UVPLASTIC provides designing and machining polycarbonate service. The subsidiary-UVACRYLIC, which is a leading manufacturer of acrylic sheets in China, provides custom acrylic. If you are interested in these products, please contact us!