Understanding the Difference Between Polycarbonate and Acrylic Sheets?

Polycarbonate VS Acrylic, which is suitable for you? Polycarbonate and Acrylic sheets are common materials in architecture, agriculture, safety & security, engineering, home decoration, medical & healthcare, transportation, POP display, and daily necessities. As a leading manufacturer of polycarbonate&acrylic, UVPLASTIC will tell you the difference between polycarbonate and acrylic sheets in this article.

What is Polycarbonate Sheet?

Polycarbonate was developed by Alfred Einhorn in 1898, who is a scientist at the University of Munich. 1953, Hermann Schnell at Bayer company developed the first linear polycarbonate. 1955, Bayer company patented it and the brand name is “Makrolon”. Almost at the same time, Daniel Fox at GE company developed polycarbonate, both companies applied for U.S. patents in 1955. Bayer began commercial production under the trade name “Makrolon” in 1958 and GE began production under the name “Lexan” in 1960.

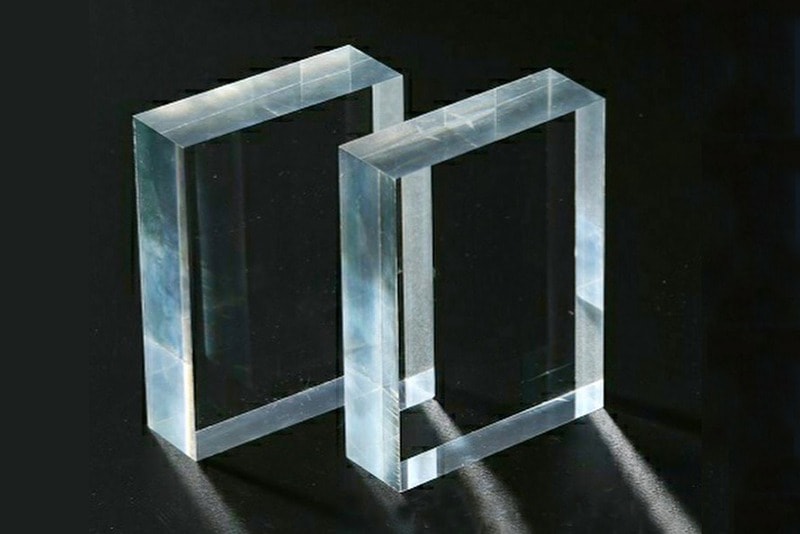

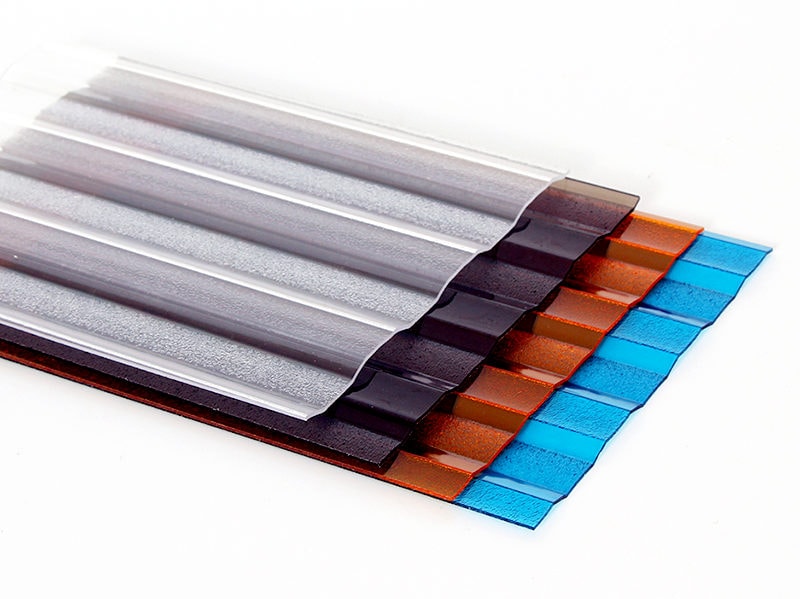

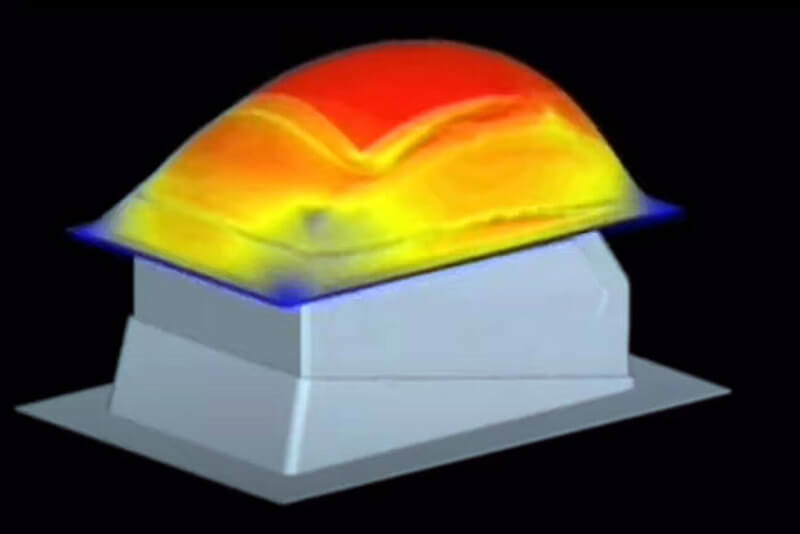

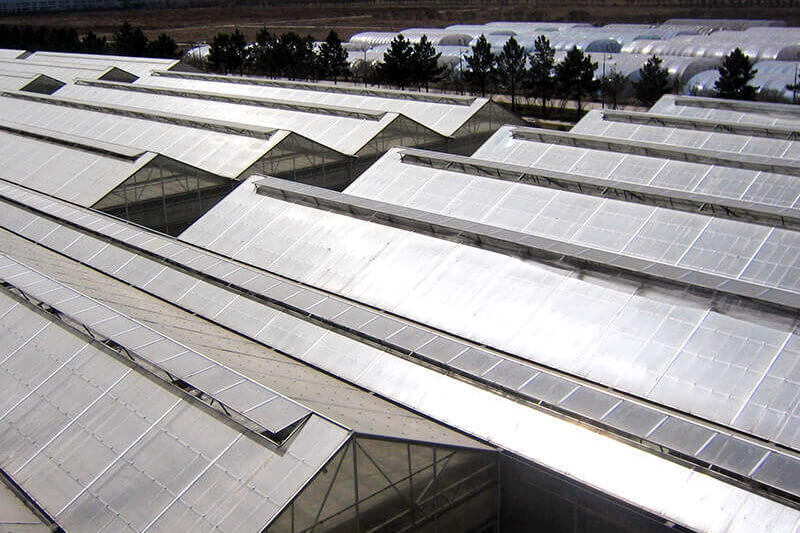

Then, a polycarbonate sheet was developed as a plastic material for making windows. They can be cut in various shapes that can be molded into almost any shape to serve as a window frame. What these materials are used for is simply to help us enhance the beauty of our windows and doors. These materials are very strong, and so they can withstand high impact if a door or window is dropped on them. These sheets also tend to be heat resistant and to be able to withstand temperatures that would normally damage any other plastic material.

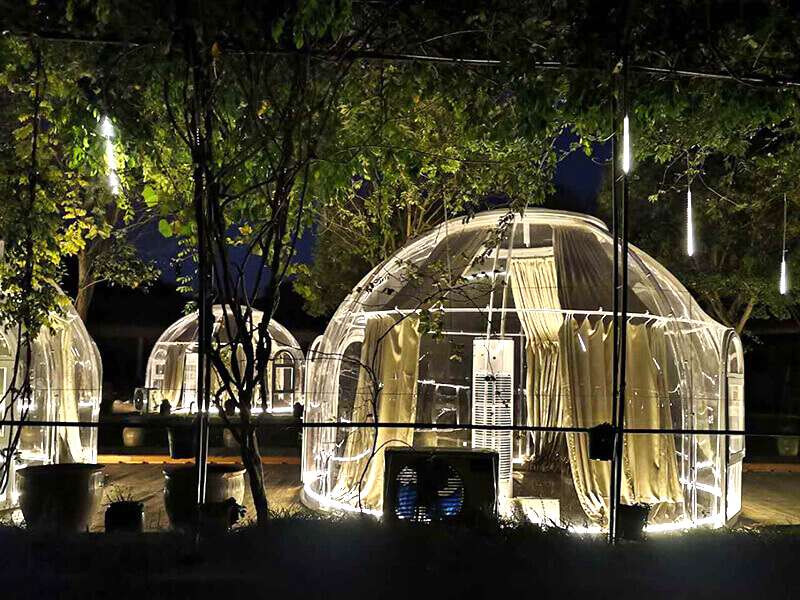

Polycarbonate sheets are mainly composed of magnesium, which helps to strengthen the plastic material. They are also made up of calcium and carbon and can help you make your windows more durable and stronger. Aside from that, they are also very sturdy and can even be treated to resist UV light. Because of all these features, it is understandable why polycarbonate sheet is often considered the best material for use in windows, doors, roofing panels, and clear bubble tent (Know more detail about the inflatable bubble tent VS clear bubble tent)

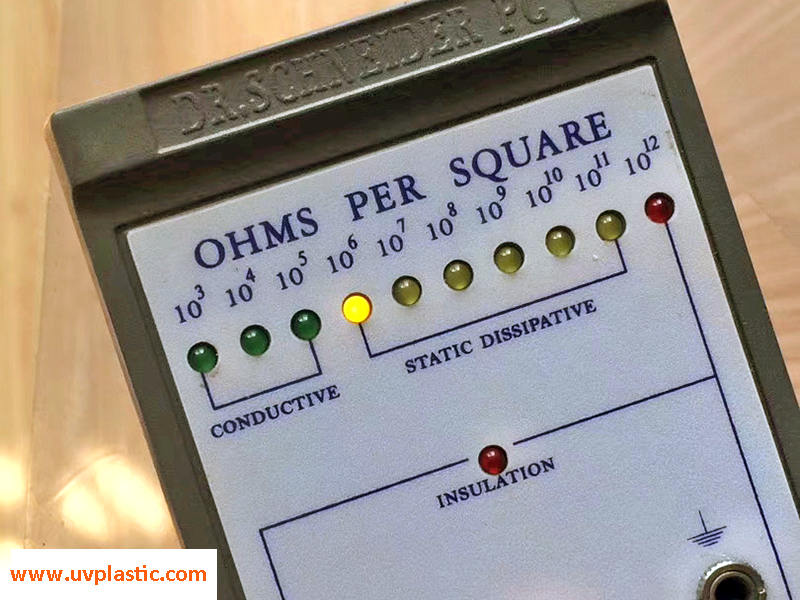

Otherwise, polycarbonate sheets can be coated with coating layers with a certain function, such as ESD coating, anti-fog coating, anti-scratch coating, and UV coating.

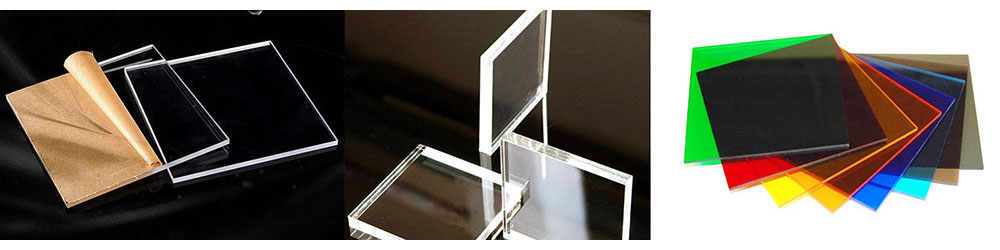

What is the Acrylic Sheet?

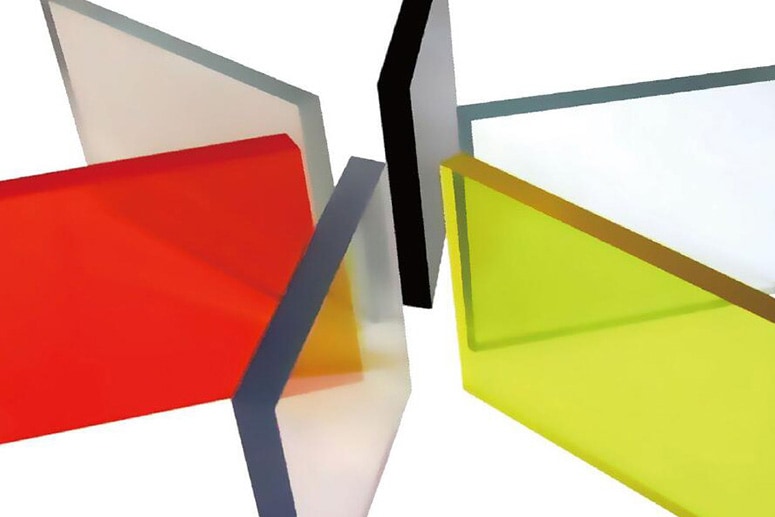

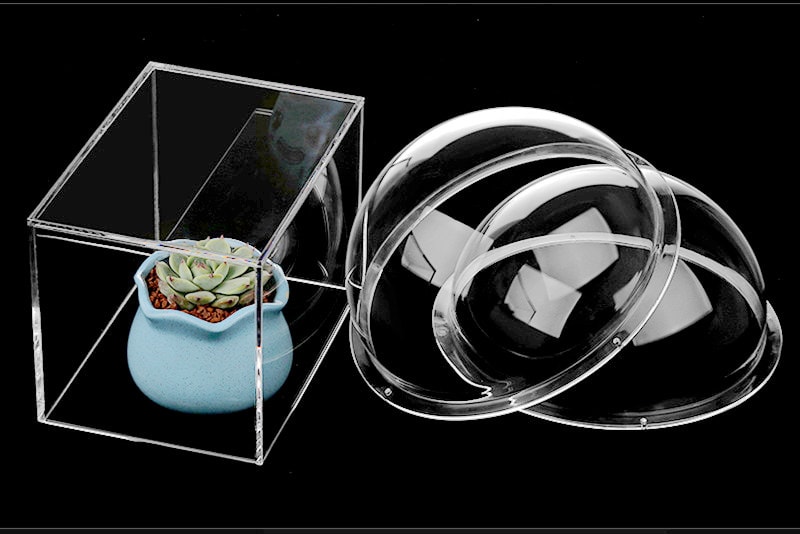

Acrylic sheets are made of polymer and carbon. Some people call it Plexiglass or PMMA Sheet, They are commonly found in offices and manufacturing facilities, because of their easy-to-use features and cost-effectiveness. It is very important to keep the surface smooth so that dust does not accumulate and get covered up. Keeping the surfaces clean and dust-free can help improve the efficiency of machinery as well as enhance the overall productivity of the business. When it comes to handling heat and moisture, acrylic sheets are designed with such characteristics so that the material stays dry and can be safely handled without any problems.

Industrial as well as other types of manufacturing companies use acrylic sheets for a variety of different purposes. This material is used in manufacturing tooling and is also used for manufacturing plastic parts. It is also used in the making of glass, wood, plastics, PVC, fiberglass, glass fiber, leather, thermal insulation, and thermal shifting. This is a versatile material, which can be shaped, cut, printed, and polished. The design possibilities for the sheet’s design and look are endless.

The Difference Between Polycarbonate and Acrylic Sheet

Different Structure

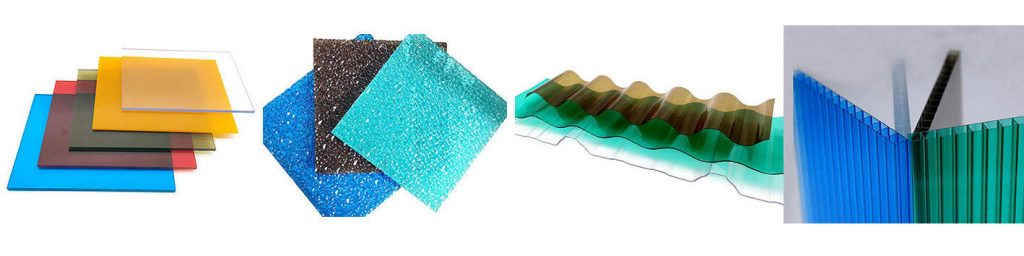

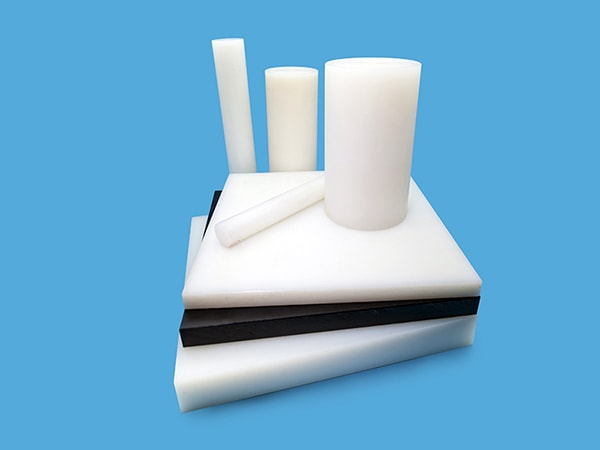

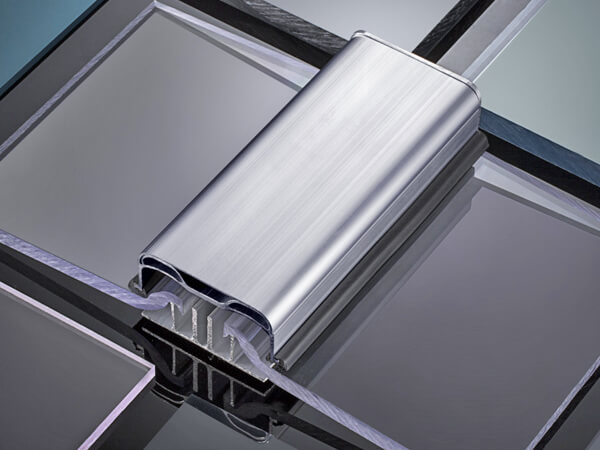

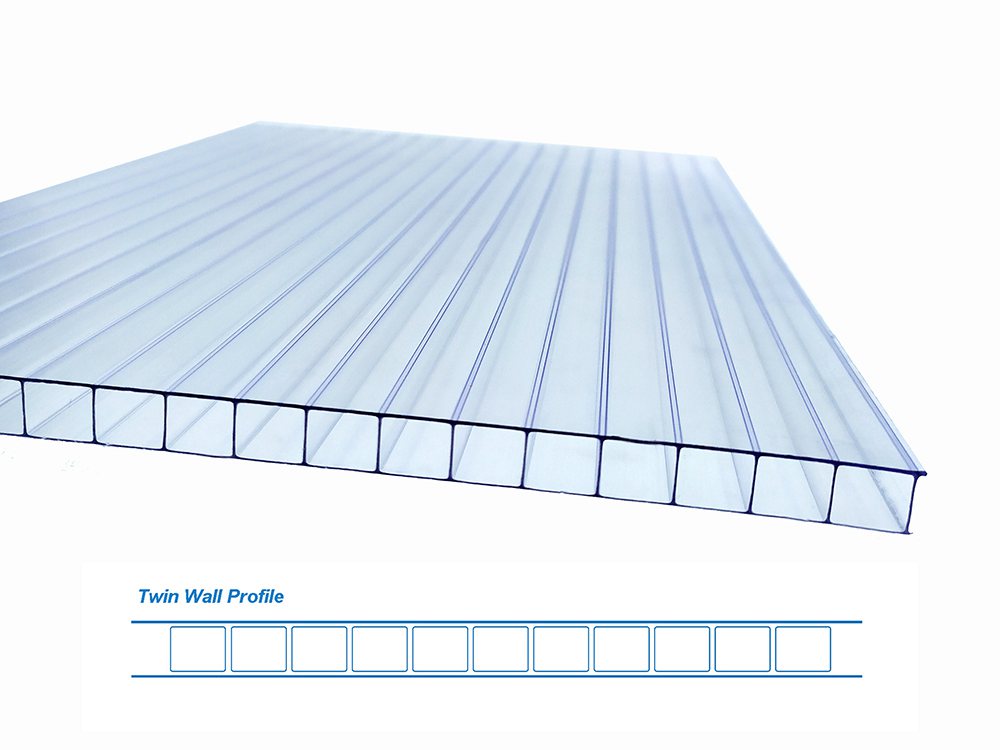

Polycarbonate can be manufactured to the structure in many forms, please see the following table for reference:

Want to know more about polycarbonate sheets and acrylic sheets.

Different Processing Method

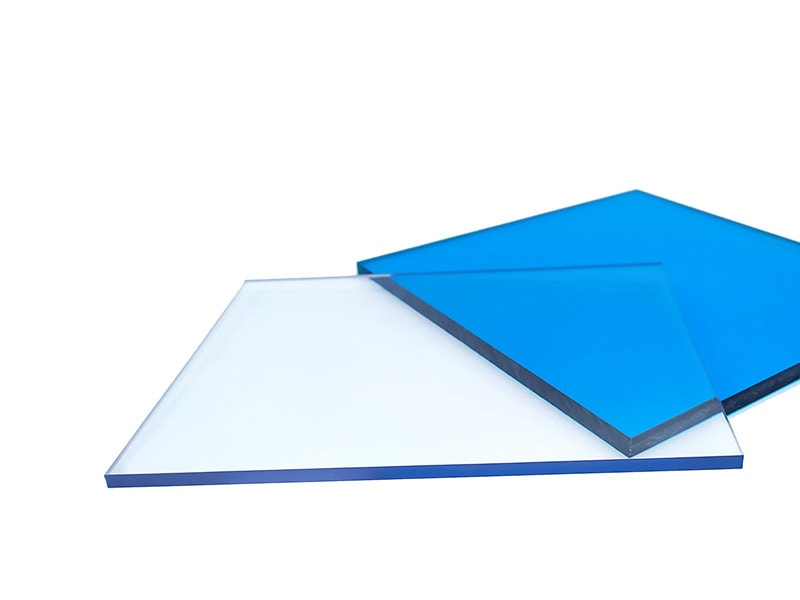

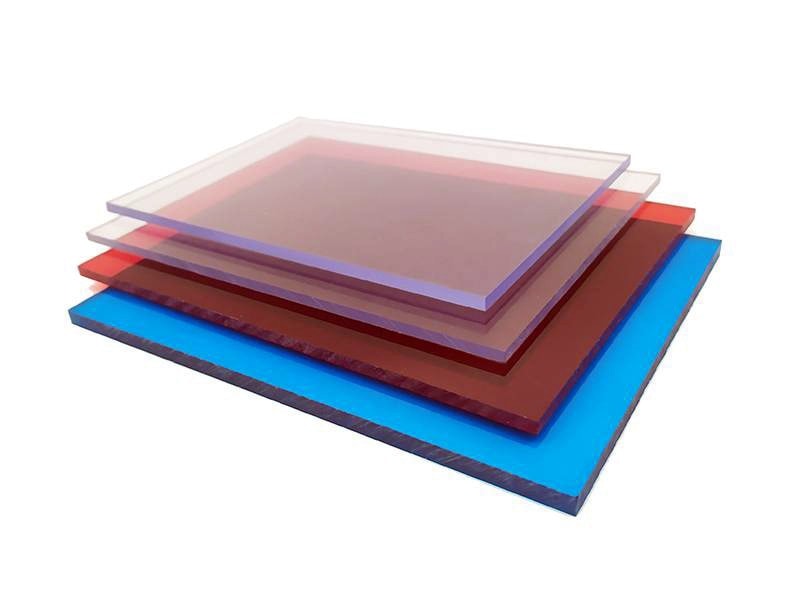

Polycarbonate and acrylic sheets can be manufactured by extruded and cast technology. But 95% of polycarbonates are extruded to be a sheet and 5% of polycarbonates are cast to be sheets, such as 40mm thick polycarbonate sheet.

80% of acrylic sheets are cast acrylic, 20% of acrylic sheets are extruded acrylic. Normally, 1mm-5mm acrylic is the extruded sheet. And acrylic film with 0.075mm thickness is extruded also. Here, maybe you want to more detail about the difference between cast acrylic and extruded acrylic.

What is an acrylic sheet used for?

As a kind of manufacturing and handling material, it is used for making precision parts, workplaces, and assemblies. For example, they are used in creating acrylic furniture, acrylic box, and acrylic frame. They are also used for making the new edge edges of furniture like tables and chairs, furniture door stops, stools, and other pieces of furniture. Many different types of furniture pieces can be made from acrylic sheets.

How to Choose the Right One Between Polycarbonate and Acrylic Sheets?

Acrylic sheets are easily the most cost-effective material that you can get in the long run. The two common choices are polycarbonate and acrylic. There are many different types of these materials, each with its advantages and disadvantages.

| Item | Acrylic, Plexiglass, PMMA Sheet | Polycarbonate Panel |

|---|---|---|

| Advantage | 10%-30% better price than polycarbonate; Easier to be polished, clean edges; Better anti-scratch than polycarbonate; Easier to glue; Max. thickness is more than 50mm or more; | More flexible than acrylic; Stronger than plexiglass sheet; Excellent heat resistance than acrylic; Good flame retardance; Can be cold-bent; Min. thickness is 0.05mm; Can be packaged to polycarbonate roll; |

| Disadvantage | Can’t cold-bent; Could be broken during drilling; The Min. thickness is 1mm; | Easy to scratch; Max. thickness is 20mm; |

Polycarbonate is a very common type of plastic, which is used in making windshields, riot shields, office chair mat, plastic face shields, clear bubble tent, and so forth. It is also used in making skis, golf balls, bicycles, snowblowers, and a lot of other things. It is cheap, strong, and easy to work with.

Polycarbonate sheets are very popular because they are very easy to work with. They can be cut, drilled, and even glued and screwed, know more about Machining Polycarbonate. It is also very easy to paint on. The biggest advantage of polycarbonate sheets is that they are ideal for interior designs. These types of sheets are lightweight, and you will not have to worry about damaging them during construction. You can use the same type of interior design sheets for both exterior and interior uses.

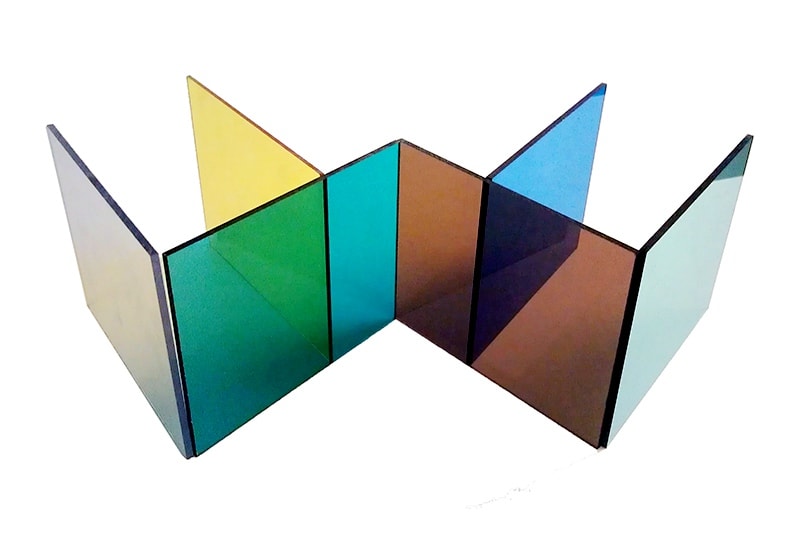

Acrylic sheets are the perfect choice for interior designs. You can still use them for exterior projects, but you will need to change the color or design once the project is complete. It is very easy to change the interior design of a building using acrylic sheets. Many interior designers like acrylic sheets because they are very durable. They can be bent and twisted without too much damage to the sheet. They are also easy to clean up. Know more about custom acrylic.

UVPLASTIC is a leading manufacturer and supplier of polycarbonate&acrylic sheet in China, we can provide high-quality in any form and integrated plastic fabrication service, If you have any questions for application, just be free to contact us.

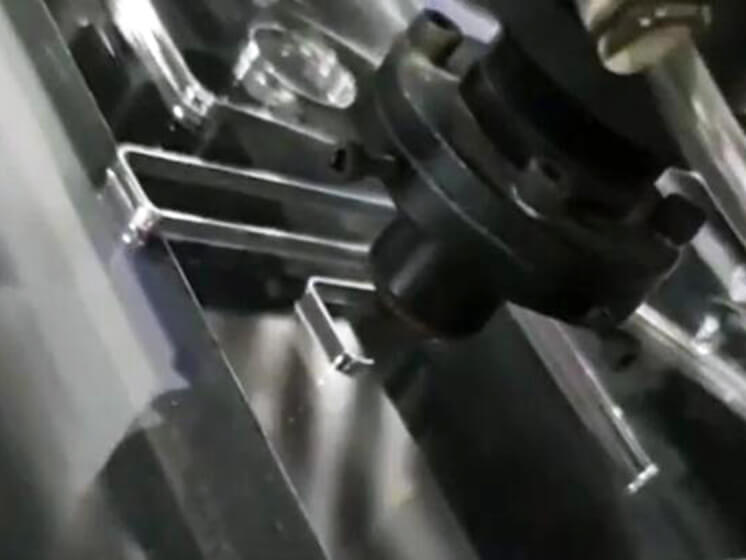

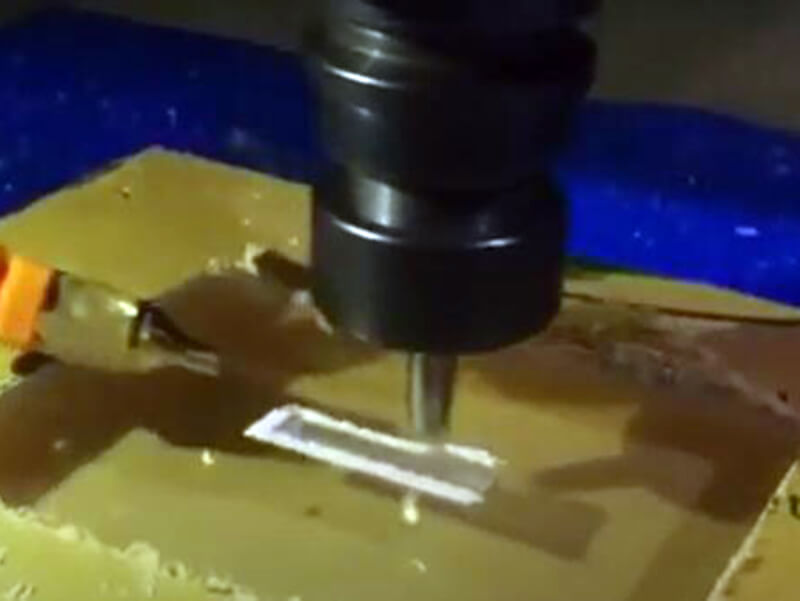

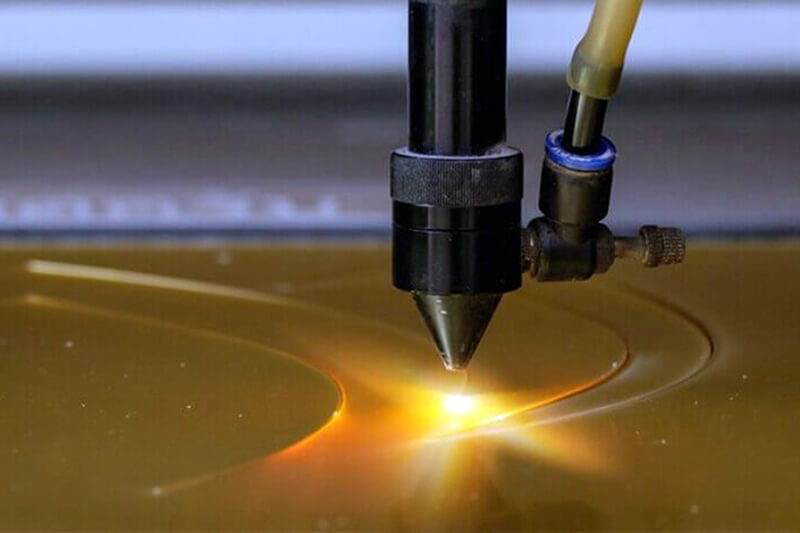

Do You Know How To Machine Polycarbonate And Acrylic?

Although polycarbonate sheet is similar to the acrylic sheet, the machining methods are different according to different material types, such as you can cold bend polycarbonate sheet, but you only bend acrylic sheet after heating. The plastic mirror is only manufactured by acrylic sheet, not polycarbonate sheet. Here, maybe you want to know the solutions of machining polycarbonate and machining acrylic.

Here are some videos of machining acrylic sheets,

Buying High-quality Polycarbonate and Acrylic from China

How to buy high-quality polycarbonate sheets and acrylic sheets in China. UVPLASTIC will be the best choice for you. UVPLASTIC is the leading manufacturer of polycarbonate sheets in China, in 2005, we built the first subsidiary-UVACRYLIC, which has grown to be the top manufacturer of acrylic sheet. This blog will tell you how to choose the right supplier in China.

2 thoughts on “Understanding the Difference Between Polycarbonate and Acrylic Sheets?”

Comments are closed.