Acrylonitrile butadiene styrene (ABS) is a common thermoplastic polymer, derived from acrylonitrile, butadiene, and styrene, the glass transition temperature is approximately 105 °C (221 °F), and it is amorphous and therefore has no true melting point.

Compared with other common polymers, ABS offers excellent mechanical properties, for example, impact resistance, toughness, and rigidity. ABS offers great chemical resistance and is resistant to aqueous acids, alkalis, concentrated hydrochloric and phosphoric acids, and animal/vegetable/mineral oils.

ABS Plastic is also a durable plastic used in a wide variety of manufacturing. Generally speaking, ABS has two major categories, one is for extrusion, and another is for injection molding, it offers excellent mechanical properties within a temperature range from −20 to 80 °C (−4 to 176 °F). Extrusion ABS can be extruded into sheets, blocks, rods, and tubes in different colors and sizes. Injection ABS can be made to any plastic part according to the injection mold.

There are many ABS grades according to different performance, for example, Machine Grade ABS, Forming Grade ABS (vacuum formable ABS), Flame Retardant ABS, ESD ABS (anti-static), 3D printing Grade ABS, etc. Machine Grade ABS is normally extruded into sheets, blocks, and rods, and is easily machined by common machining processes including turning, drilling, milling, sawing, electroplating, and dyeing/painting.

As one of the popular engineering plastics, ABS is used frequently in wide applications, for example, Automotive, Aerospace and Aircraft, Electronics, Construction, Medical and Pharmaceutical, Food and Beverage, Home Appliances, etc.

ABS Plastic in all forms that UVTECO Can Supply

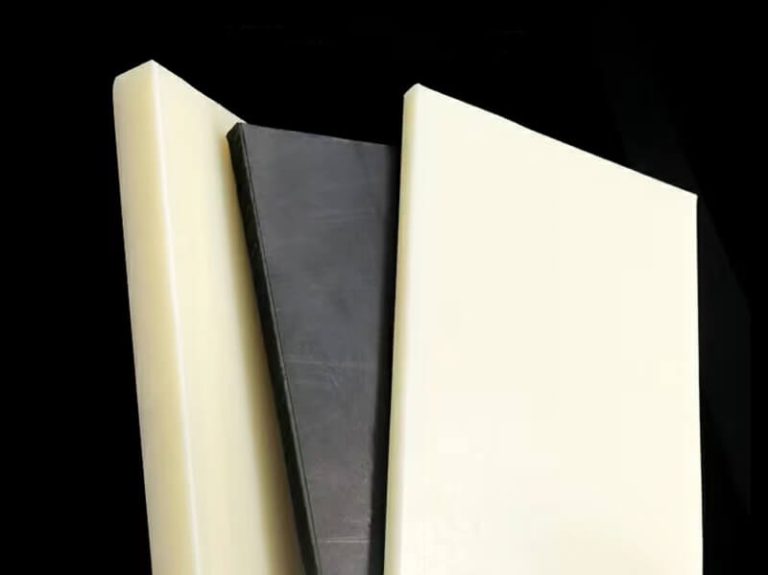

ABS Plastic Sheet

There are many different ABS plastic sheets according to different physical properties, including vacuum forming ABS sheets, Machine Grade ABS sheets, Static Control ABS sheets, and Flame retardant ABS sheets, the thickness from 0.8mm to 200mm.

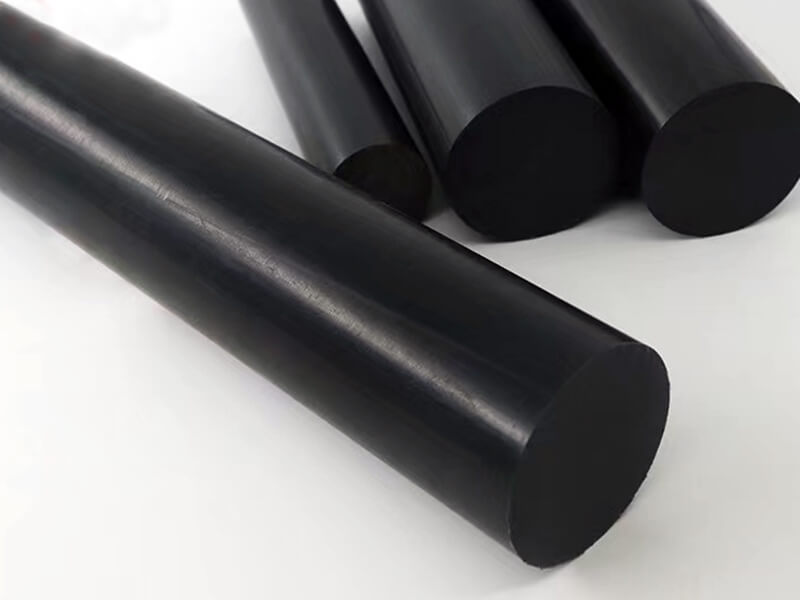

ABS Plastic Rod

ABS Plastic Rod is extruded from Acrylonitrile butadiene styrene plastic, the normal colors include nature and black, and the diameter is from 2mm to 250mm. ABS Plastic Rod is used for plastic parts by CNC lathe turning.

UVTECO stocks ABS Plastic Rods with diameters from 2mm to 80mm for fast delivery, meantime, we can machine it according to drawings.

| Item | Color | Diameter (mm) | Standard Length (mm) |

|---|---|---|---|

| ABS Rod | Nature color, black, White | 2mm, 3mm, 4mm, 5mm, 6mm, 8mm, 10mm | 1000mm, 2000mm |

| ABS Rod | Nature color, black | 12mm, 15mm, 20mm, 25mm, 30mm, 35mm, 40mm, 45mm | 10000mm |

| ABS Plastic Rod | Nature color, black | 50mm, 55mm, 60mm, 65mm, 70mm, 75mm, 80mm | 1000mm |

Basic Information

| Item | Description |

|---|---|

| Product name | ABS Plastic (Acrylonitrile Butadiene Styrene) |

| Available color | Nature color, black, White |

| Thickness range | From 0.2mm to 200mm |

| Grade | Vacuum Forable ABS, Machine Grade, ESD (Static control) ABS, Flame retardant ABS |

Physical Properties

| Physical Properties | Testing Method | Unit | Value |

|---|---|---|---|

| Density | ASTM D792 | g/cc (g/m^3) | from 1 to 1.1 |

| Water Absorption. 24 hrs | ASTM D570 | % | 0.4 |

Mechanical Properties

| Mechanical Properties | Testing Method | Unit | Value |

|---|---|---|---|

| Tensile yield strength | ASTM D638 | psi/MPa | 6.5K/45 |

| Tensile Elongation (Break) | ASTM D638 | % | 45 |

| Flexural Strength | ASTM 790 | psi/MPa | 9000/62 |

| Flexural Modulus | ASTM 790 | psi/MPa | 260K/1800 |

| Shore Hardness | ASTM D2240 | D | 75 |

| Impact strength | ASTM D256 | J/M | 185 |

Thermal Properties

| Thermal Properties | Testing Method | Unit | Value |

|---|---|---|---|

| Melting point | DSC | °F/°C | 302/150 |

| Heat deflection temperature | ASTM D648 | °F/°C | 176/80 |

| Long-time operating temperature | °F/°C | 158/70 | |

| Short-time operating temperature | °F/°C | 194/90 | |

| Coefficient of Linear Thermal Expansion | ASTM D696 | W/(K-M) | 9 |

Feature

Applications

Can’t find what you need? Or need a custom ABS Plastic?

Leading Supplier of ABS Plastic In China

UVTECO is one of the leading suppliers of ABS plastic in China, we are stocking the frequently-used ABS for fast delivery, including ABS Sheets, ABS rods. Meantime, UVTECO is providing the integrated machining solution for ABS-based parts/components, the main machining methods include cutting, drilling, 3-axis & 5-axis CNC milling, CNC Turning, injection molding, thermal forming, engraving, etc.

As an ISO-certificated company, UVTECO is providing high-quality ABS-based products, parts/components for more than 2500 clients from more than 45 countries, they are working in automation, automobile industry, medical industry, aerospace industry, appliance industry, and electrical & electronic, etc.

Contact UVTECO for machining Polycarbonate service

Contact UVTECO

Have questions or need help? Fill out the right form, we will be in touch with you as quickly as possible.