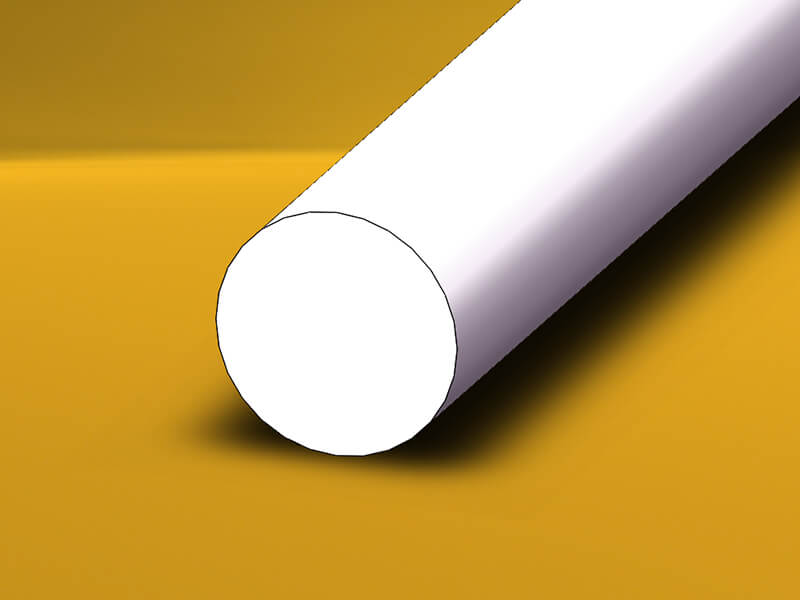

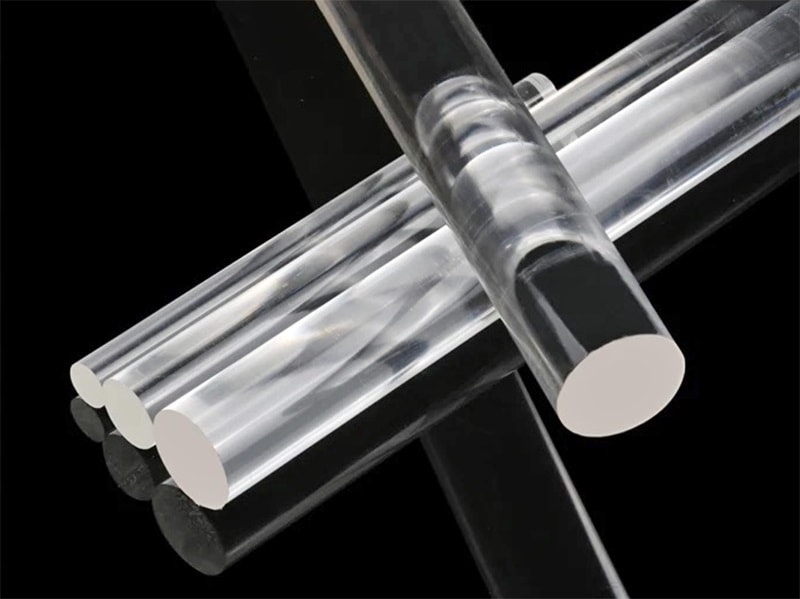

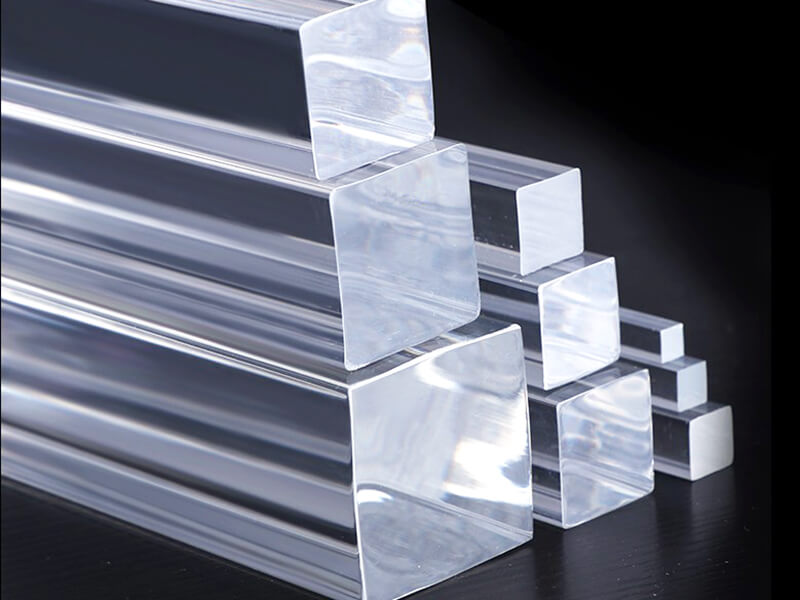

Acrylic Rod in All Forms

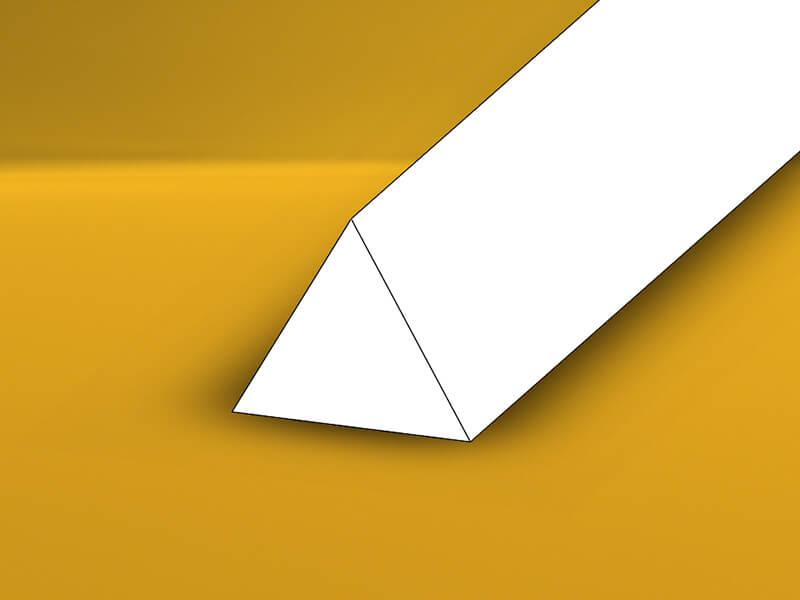

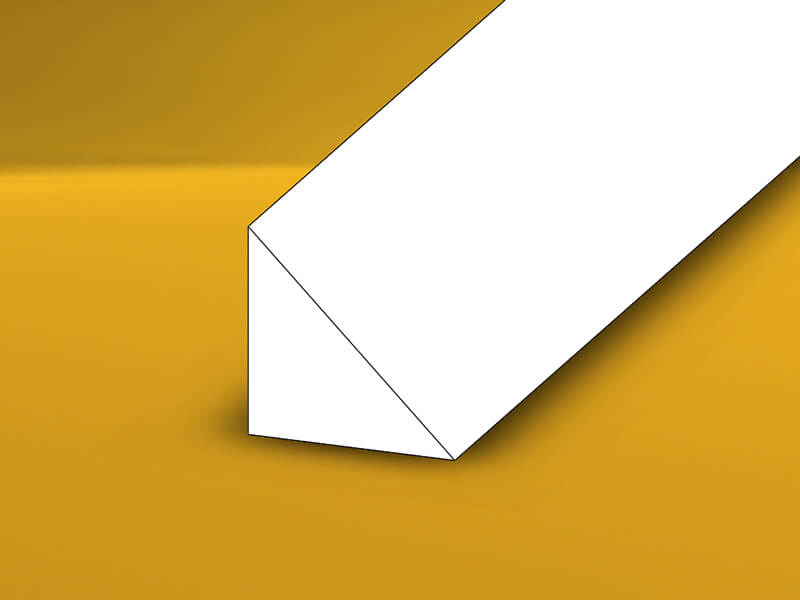

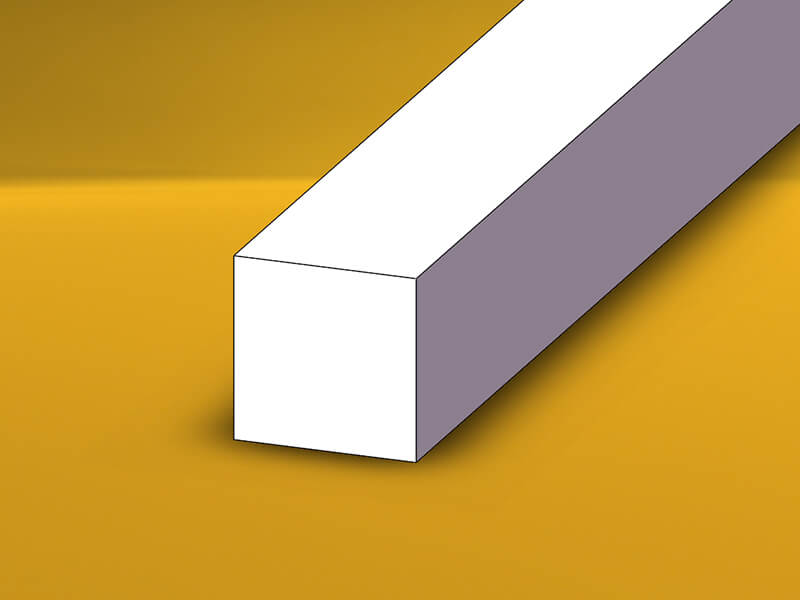

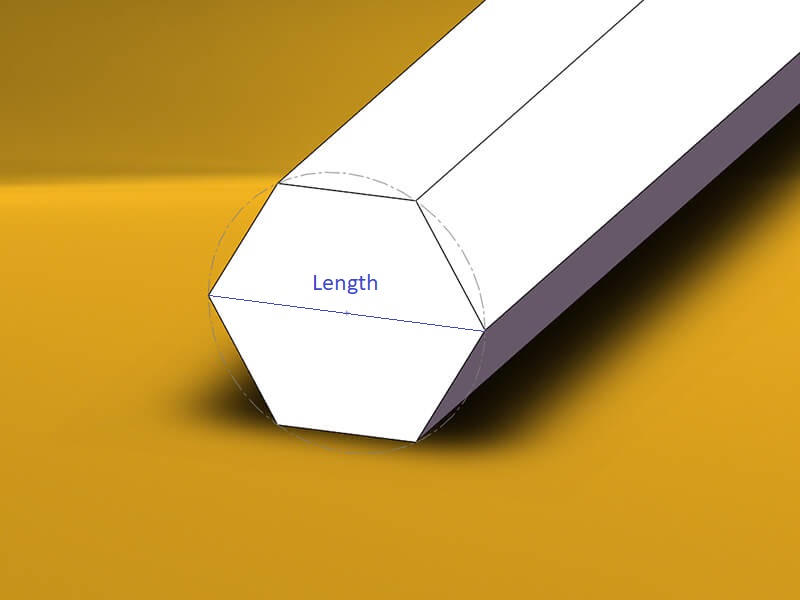

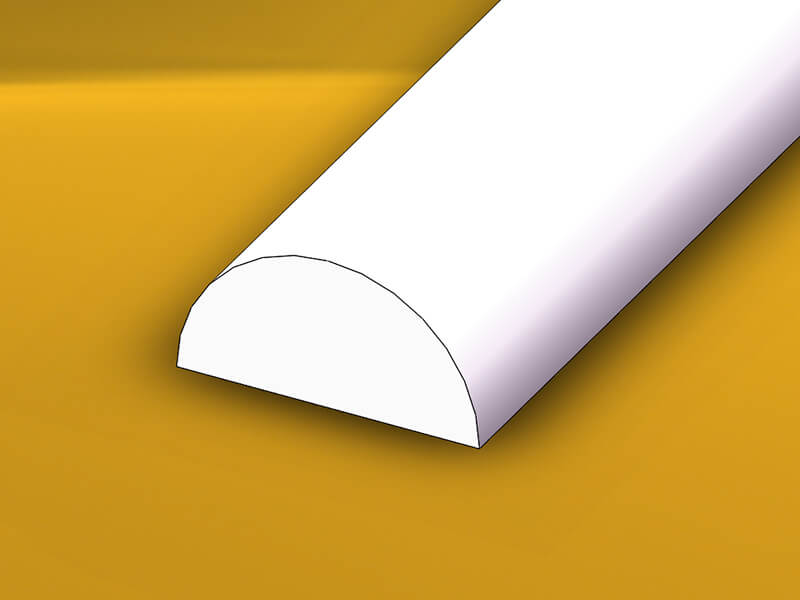

Round, Triangle, Square, Hexagon, semicircular Acrylic Rod…

Top Supplier of Acrylic/Plexiglass Rods

Acrylic Rod is an excellent plastic rod, manufactured by extrusion or casting process, which is also called as “Plexiglass rod” or “Lucite rod“. It is a common substitute for the glass rod as it is crystal clear, lighter weight, more shatter-resistant, and easy to be bonded, fabricated, formed or CNC turned. Otherwise, acrylic rods can be clear, colored, fluorescent, and custom colors. The cross-section could be round, triangle, square, hexagon, semicircular, and custom shapes.

As a flexible plastic rod, the acrylic rod offers 15 times of impact strength more than the equivalent glass rod but half weight. Meantime, it has superior chemical resistance, UV resistance, and weather ability, therefore, the acrylic rod is suitable for both indoor and outdoor applications, for example, staircase banister spindle, light guide rods, acrylic curtain rods, acrylic dowel, acrylic drapery rod, and acrylic furniture, etc.

UVACRYLIC is a top supplier of acrylic/plexiglass rods in China. With more than 15 years of experience in this field, we provide standard products with diameters from 2mm to 400mm. Normally, we have enough stock of standard rods for fast delivery. Meantime, we provide colored acrylic rods and custom acrylic rods, such as triangle, square, hexagon, semicircular, or other custom shapes, the length can be customized. UVACRYLIC also provides machining services according to clients’ requirements, for example, Cutting to Size, CNC turning, Bonding, Polishing Surface, Thread Tapping, etc.

Plexiglass/Acrylic Rod Details

Product Range

| ItemsemicircleItem | Model | Color Options | Dimension Range |

|---|---|---|---|

| Round Plexiglass Rod | UVACR-RO | Transparent, Translucent, Opaque | Diameter: From 2mm to 400mm |

| Equilateral Triangle Rod | UVACR-ETR | Transparent, Translucent, Opaque | Edge Length: From 10mm to 50mm |

| Right Triangle Rod | UVACR-RTR | Transparent, Translucent, Opaque | Altitude/base edge length: From 3mm to 50mm |

| Square Plexiglass Rod | UVACR-SQ | Transparent, Translucent, Opaque | Edge Length: From 8mm to 160mm |

| Hexagon Plexiglass Rod | UVACR-HE | Transparent, Translucent, Opaque | Diagonal Length: From 15mm to 50mm |

| Semicircle Acrylic Rod | UVACR-SE | Transparent, Translucent, Opaque | Diameter: From 10mm to 60mm |

| Custom Plexiglass Rod | UVACR-CU | Transparent, Translucent, Opaque | According to clients’ requirement |

Dimension of Acrylic Rods

| Dimension In Millimeter | Dimension In Inch | Round Rod UVACR-RO | Equilateral Triangle Rod UVACR-ETR | Right Triangle Rod UVACR-RTR | Square Rod UVACR-SQ | Hexagon Rod UVACR-HE | Semicircle Acrylic Rod UVACR-SE |

|---|---|---|---|---|---|---|---|

| 2mm | 3/64 in | ✔ | ✔ | ||||

| 3mm | ✔ | ✔ | |||||

| 4mm | 5/32 in | ✔ | ✔ | ||||

| 5mm | ✔ | ✔ | |||||

| 6mm | 15/64 in | ✔ | ✔ | ||||

| 8mm | 5/16 in | ✔ | ✔ | ||||

| 10mm | 25/64 in | ✔ | ✔ | ✔ | ✔ | ✔ | |

| 12mm | 15/32 in | ✔ | ✔ | ||||

| 15mm | 19/32 in | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| 18mm | 23/32 in | ✔ | |||||

| 20mm | 25/32 in | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| 24mm | ✔ | ||||||

| 25mm | 1 in | ✔ | ✔ | ✔ | ✔ | ||

| 30mm | 1-1/4 in | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ |

| 35mm | ✔ | ||||||

| 40mm | ✔ | ✔ | ✔ | ✔ | ✔ | ✔ | |

| 45mm | ✔ | ||||||

| 50mm | 2 in | ✔ | ✔ | ✔ | ✔ | ||

| 60mm | ✔ | ✔ | |||||

| 70mm | ✔ | ✔ | ✔ | ||||

| 80mm | ✔ | ✔ | |||||

| 90mm | ✔ | ✔ | |||||

| 100mm | 4 in | ✔ | ✔ | ✔ | |||

| 110mm | ✔ | ||||||

| 120mm | ✔ | ||||||

| 150mm | 6 in | ✔ | |||||

| 160mm | ✔ | ||||||

| 180mm | ✔ | ||||||

| 200mm | 8 in | ✔ | |||||

| 220mm | ✔ | ||||||

| 250mm | 10 in | ✔ | |||||

| 300mm | 12 in | ✔ | |||||

| 350mm | 14 in | ✔ |

What You Need To Know About Acrylic Rod

Physical Properties

| Properties | Unit | Value |

|---|---|---|

| Properties | Unit | Value |

| Density (clear arcylic) | g/cm^3 | 1.19 |

| Tensile Strength | Mpa | >70 |

| Charpy impact strength (unnotched) | KJ/m^2 | >13 |

| Tension Modulus of Elasticity | Mpa | >3000 |

| Tensile Strain at break | % | >4 |

| Flexural strength | Mpa | 100 to 115 |

| Charpy impact strength (unnotched) | kj/m^2 | >17 |

| Vicat softening temperature | °C | >105 |

| Dimensional change on heating (shrinkage) | % | <2.5 |

| Total luminous transmittace | % | >90 |

| Rockwell hardness | 100 to 115 | |

| Linear expansion coefficient | K^ -1 | 7×10^-5 |

| Temperature of deflection under load | °C | 95 to 100 |

| Light transmittance | % | >90 |

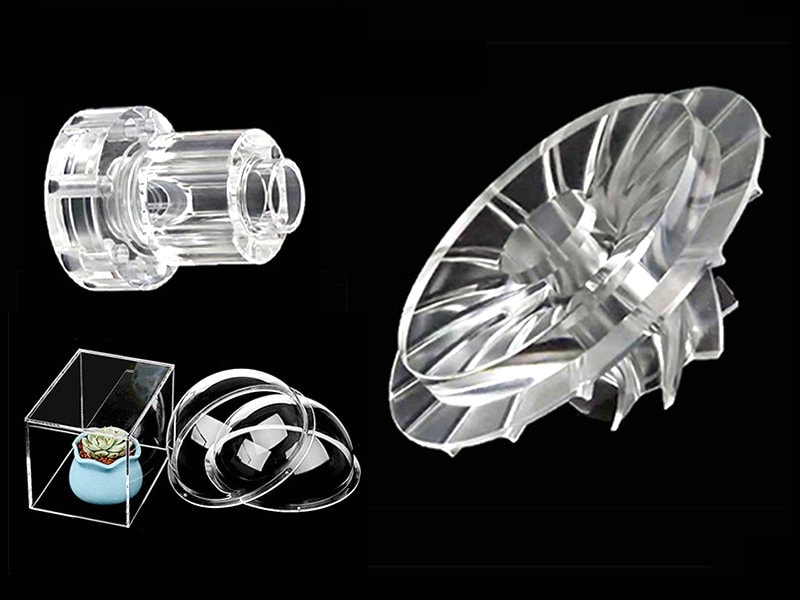

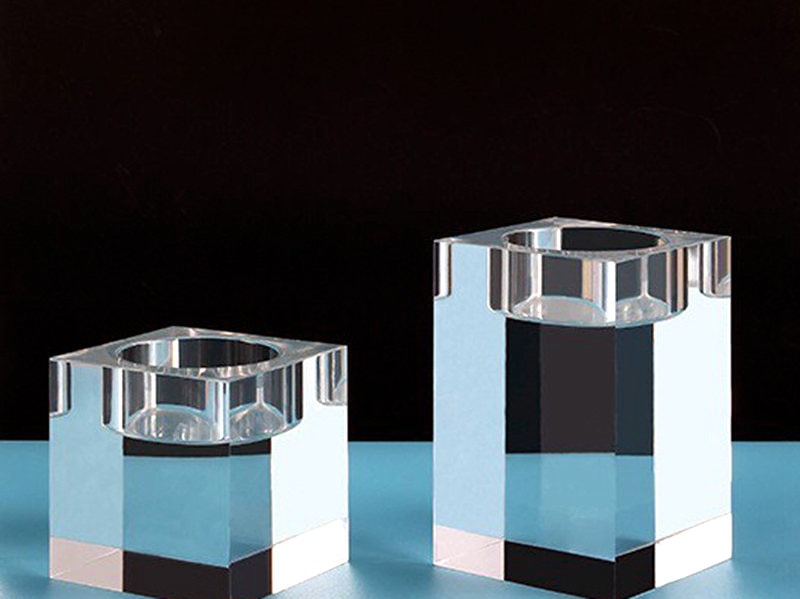

Machining Service

With more than 15 years of experience in machining acrylic, UVACRYLIC provides integrated machining solutions for custom acrylic. Today, we have grown to be the top OEM factory of acrylic-based products.

The common machining acrylic methods include cutting, polishing, bending, gluing, coating, CNC Machining, Printing, Drape forming, Injection Molding, Blow Molding, etc.

From common machining, methods, our engineers always find the right solution for all acrylic-based products.

Typical Applications of Acrylic Rod

Manin Benefits Of Acrylic Rods

100% Environment-Friendly PMMA Material

Purchased From Lucite And MITSUBISHI Company Directly