everything comes FROM material AND machining SOLUTION

New Material R&D

UVTECO is Working with Global Clients for New materials, which offer particular properties.

Materials

UVTECO is a top manufacturer & distributor of Engineering Plastic, Foam & Sponge, Rubber, Metal, etc.

UVTECO material range

Material in stock for fast delivery

UVTECO stocks Engineering Plastic, Foam, Rubber, Metal, etc, which are used frequently for industrial parts/components. In this case, we can deliver these materials to global clients quickly.

Engineering plastic

Sheets, Blocks, Films, Rods, and Tubes made by PC, PP, PMMA, PA, PEEK, etc.

Foams & Sponge

Conductive Foam, ESD Foam, EVA Foam, Silicone Foam, Neoprene Sponge Foam, Polyurethane Foam, Elastomeric Foam, PE Foam, etc.

rubber

Neoprene Rubber, EPDM Rubber, Nitrile Rubber, Silicone Rubber, SBR Rubber, etc.

Metal

Alloy Steel Aluminum, Stainless Steel, Copper, Silver, Gold, etc.

Custom Manufacturing From Designing to High-Volume Production

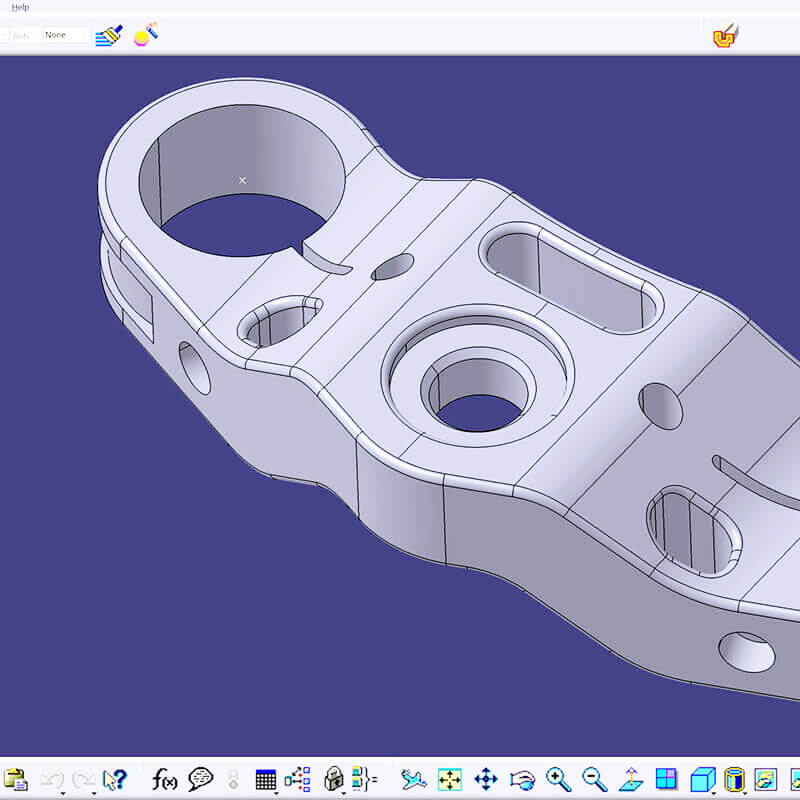

Industrial Parts Design

By Using Software including SolidWorks, UG, and CATIA, we work with global clients to design components.

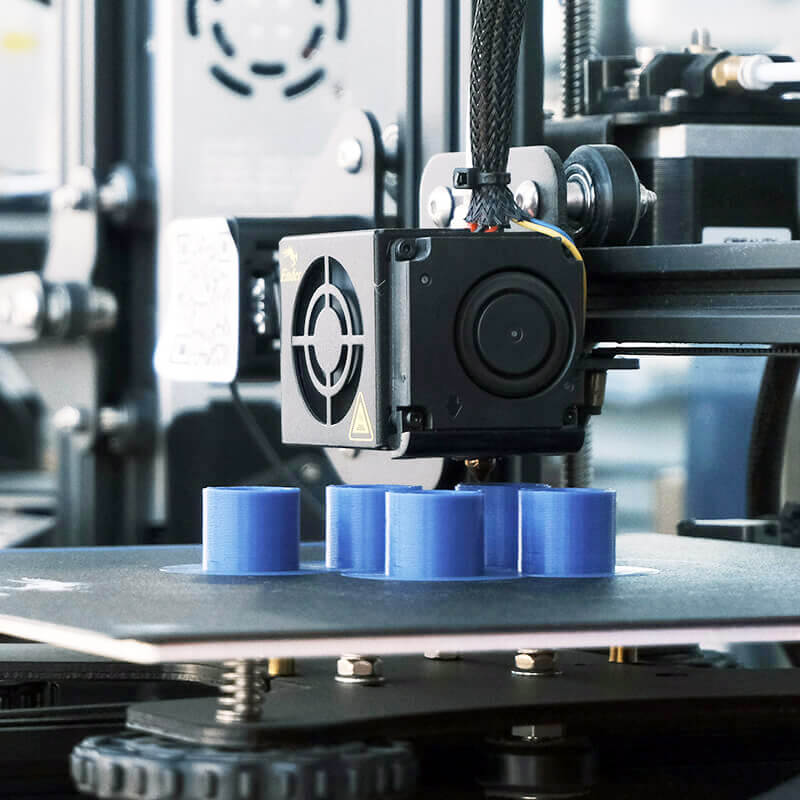

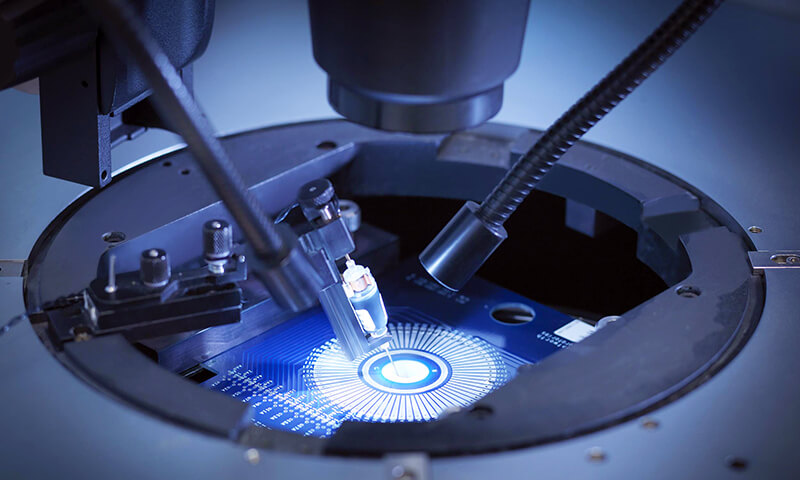

Rapid Prototyping

UVTECO provides ONE-STEP rapid prototyping services to support every process of product development from the global market.

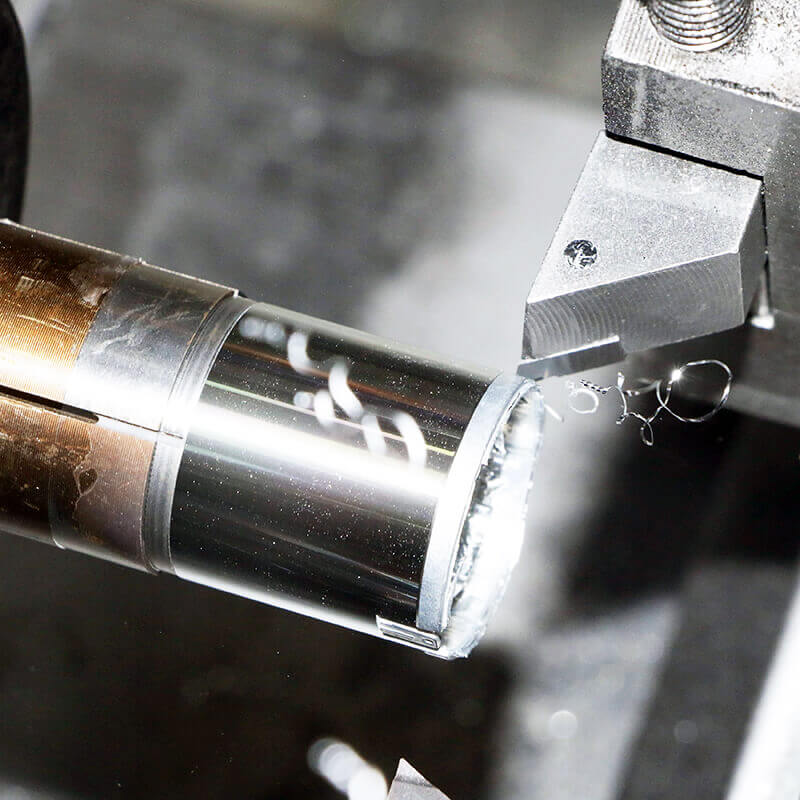

Low-Volume manufacturing

UVTECO helps global clients get to market faster by providing cost-effective and fast low-volume manufacturing services.

high-volume production

With knowledge and experience in materials and machining processes, UVTECO provides OEM services for high-volume production.

KNOW MATERIAL, KNOW MACHINING

our advantage

your right partner for parts/components

With more than 30 years of experience in the industrial field, UVTECO has grown to be a leading supplier of materials and provider of OEM services for industrial parts.

UVTECO offers comprehensive capabilities including in-house machining and integration of manufacturing resources in China. We are always ready to support you with not only suitable materials but also integrated machining solutions.

our Clients

what our clients say

With high-quality products and superior service, we are working with more than 2000 clients from more than 40 countries.

Thomas Kruck

Munich, Germany

“UVTECO supplied Polycarbonate Diffuser Parts, which will be used as a part of the PHUD, we are very happy with them, and will order more in the future.”

Tsugumi Susaki

Tokyo, Japan

“We ordered Aluminum Parts in low volume, we are very excited about the fast delivery and good quality, UVTECO helps us to get more orders from our clients.”

Carrié Charles

Paris, France

“We have been working with UVTECO for more than 9 years, I am very impressed with their high efficiency and professional in material and machining capability.”

Norman Engel

Texas, America

“We are very happy to work with UVTECO because they provided very cost-effective parts, and saved lots of cost by developing new materials for our projects.”

industries we are working for

Agriculture

Agriculture Aircraft & Aerospace Industry

Aircraft & Aerospace Industry Automation Equipment

Automation Equipment Automobile Industry

Automobile Industry Construction Industry

Construction Industry Consumer Electronics

Consumer Electronics Green Energy Industry

Green Energy Industry Home Appliance

Home Appliance Medical Industry

Medical Industry Metaverse

Metaverse Military Equipment

Military Equipment Recreational Machines

Recreational Machines Semiconductor Industry

Semiconductor Industry Telecommunications

Telecommunications Energy Industry

Energy Industry