How to cut polycarbonate

Related Machining Process

Printing Plastic

Bending Polycarbonate

Rapid Prototype

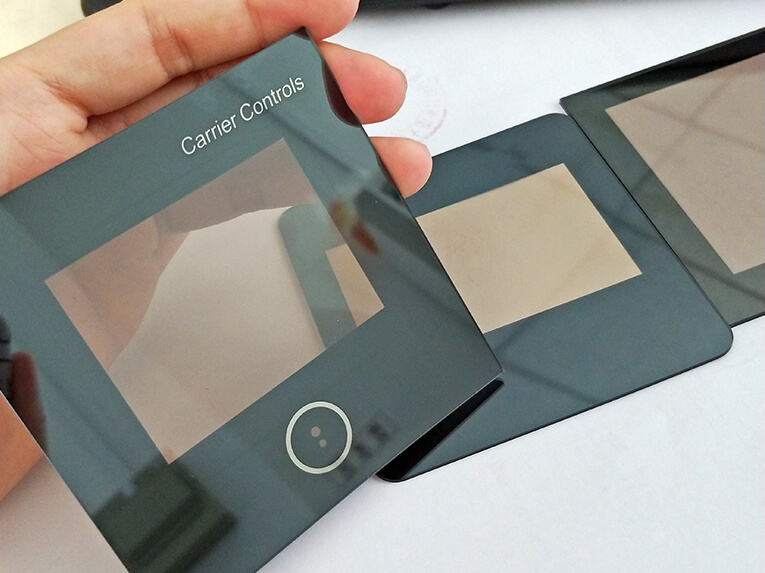

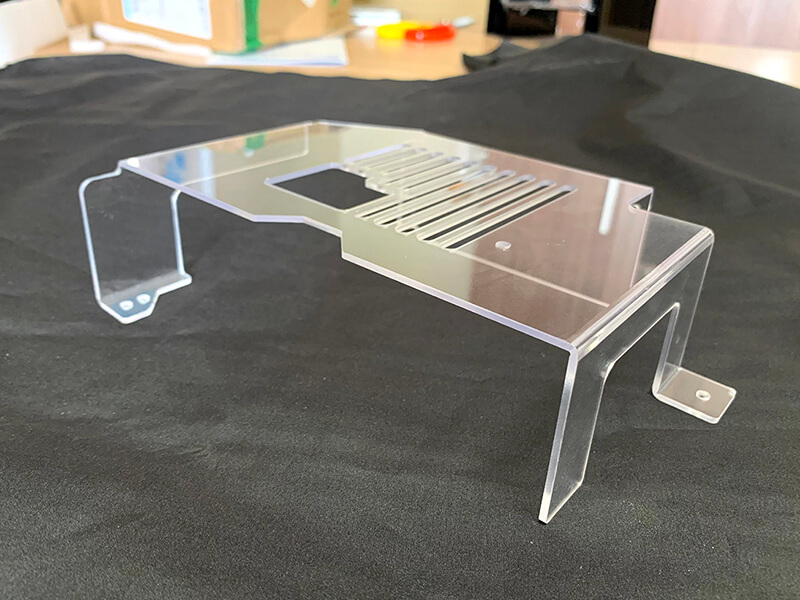

How to cut polycarbonate? Most people have experience in cutting it for polycarbonate parts because polycarbonate is one of the engineering plastic for medical equipment, pinball machines, aeronautical facilities, machine guard board, construction industry, semiconductor devices, automobiles, furniture, automation, etc. If you are looking for a supplier for cutting polycarbonate, UVPLASTIC is one of the best choices.

What is polycarbonate?

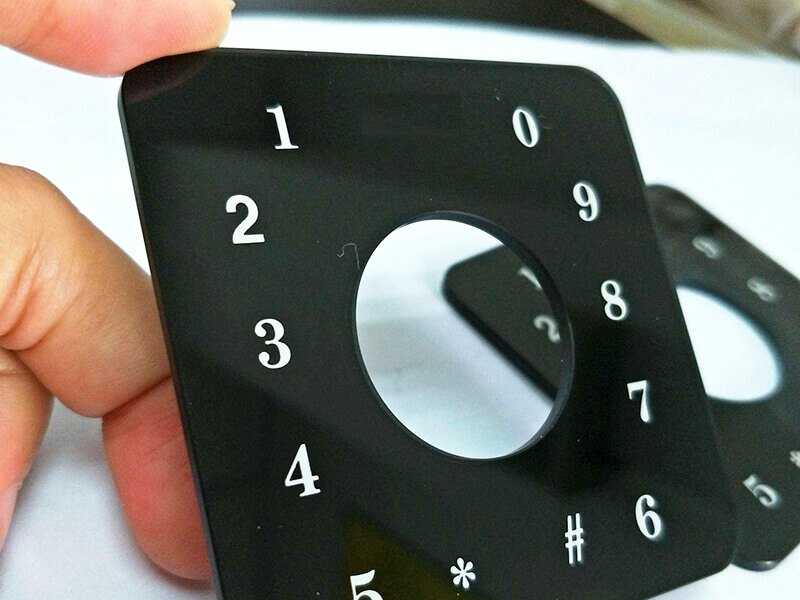

Polycarbonate is a tough, transparent engineering plastic material with outstanding strength, stiffness, and impact resistance. It can be manufactured to panel, film, rod, tube, and complicated shapes by injection molding. They are easily machined, molded, thermoformed, and printed, therefore, there are many applications for polycarbonates, for example, machine guards, safety glass, signs, architectural glazing, face shields, skylights, POP displays, etc.

Why should you cut polycarbonate?

Polycarbonate material is powder-like or granulated resin with transparent or white color and manufacturers machine it to a panel, film, rod, tube, or definite shape by injection molding.

For polycarbonate panels, polycarbonate film, the standard width is 1830mm, 1200mm, 2100mm, the length can be customized. But these sizes are not suitable for applications, therefore, we need to cut them to size.

For rod and tube, the diameter is standard, and the length is about 2 meters or longer. We need to machine the diameter to be suitable. Therefore, cutting polycarbonate is necessary.

For polycarbonate roofing sheets, the width is standard, sometimes, the length is not suitable for different roofs of houses. You need to cut it for your roof.

Cutting polycarbonate methods

There are many methods to cut polycarbonate according to shape, size, thickness, the number of polycarbonate parts, etc. The normal methods are following:

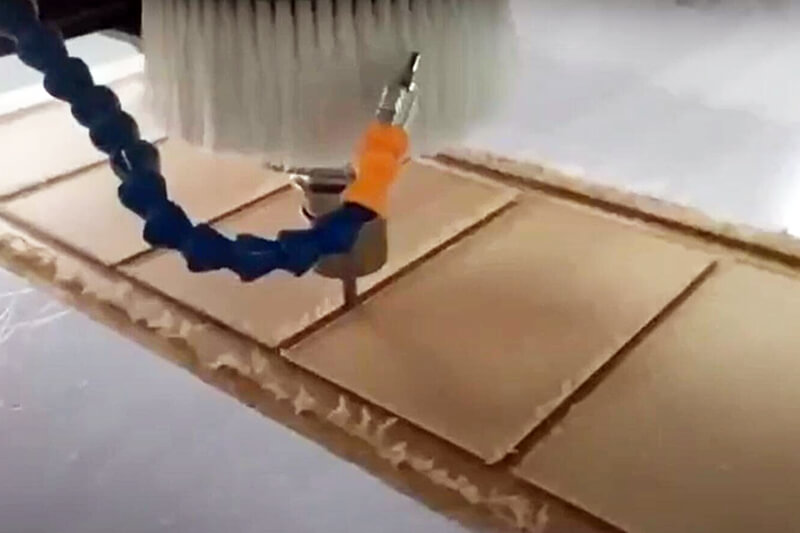

Cutting Polycarbonate by CNC Router

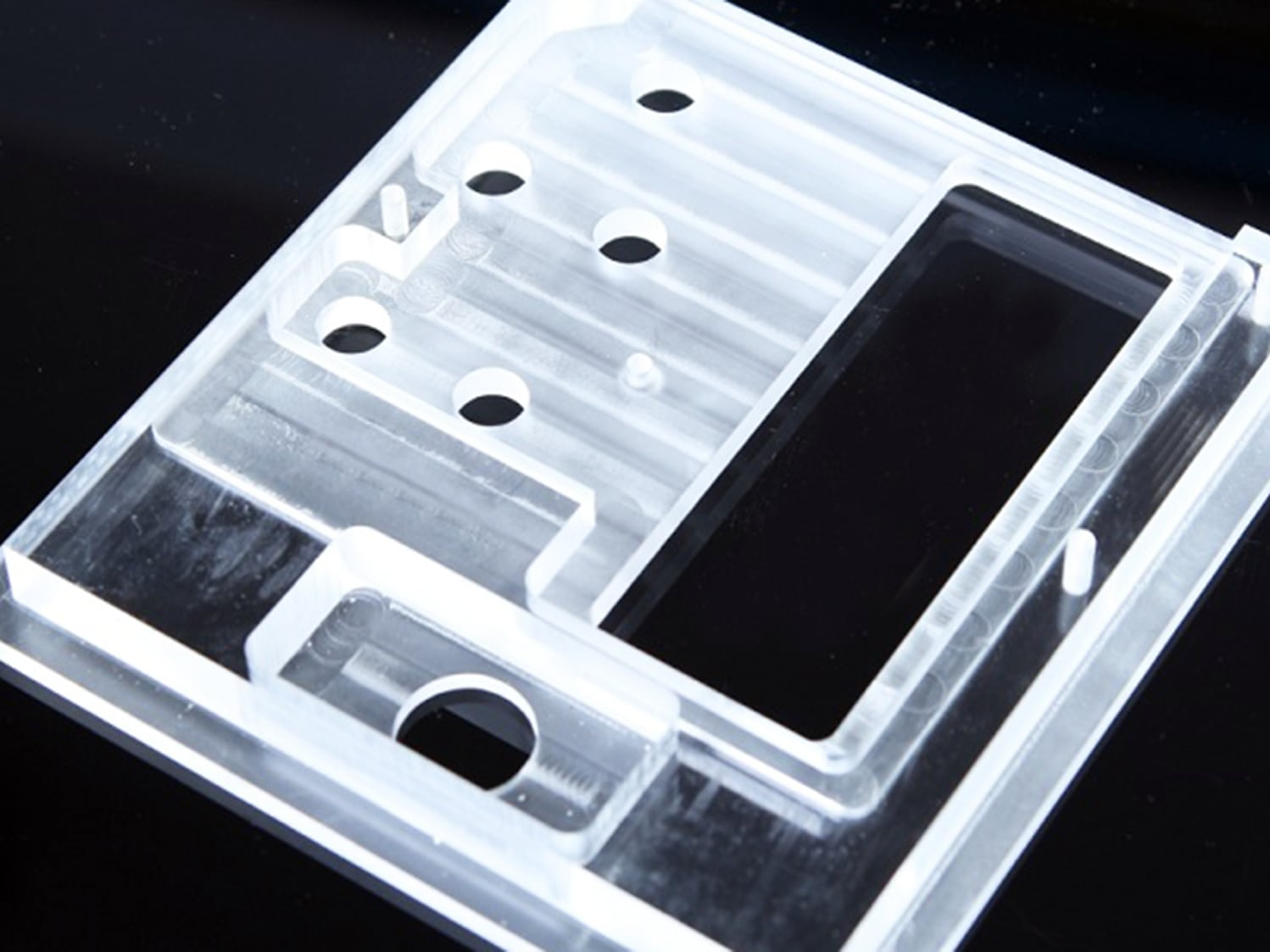

CNC router is the popular method for professional suppliers of machining polycarbonate, somebody call this method “CNC milling” because it is precise, high-effective, automated and it can cut polycarbonate to very complicated shapes including holes. After polishing, the surface is mirror-like.

| Suitable product | Advantage | Disadvantaged |

|---|---|---|

| Polycarbonate film; Polycarbonate sheet; | 1. Automated machining method; 2. Can machine complex shapes; 3. High-precision; 4. High-effective for mass products; | 1. CNC Router is expensive, it is not suitable for individuals; 2. Not suitable for polycarbonate tube/rod; |

Cutting Polycarbonate by hand saw

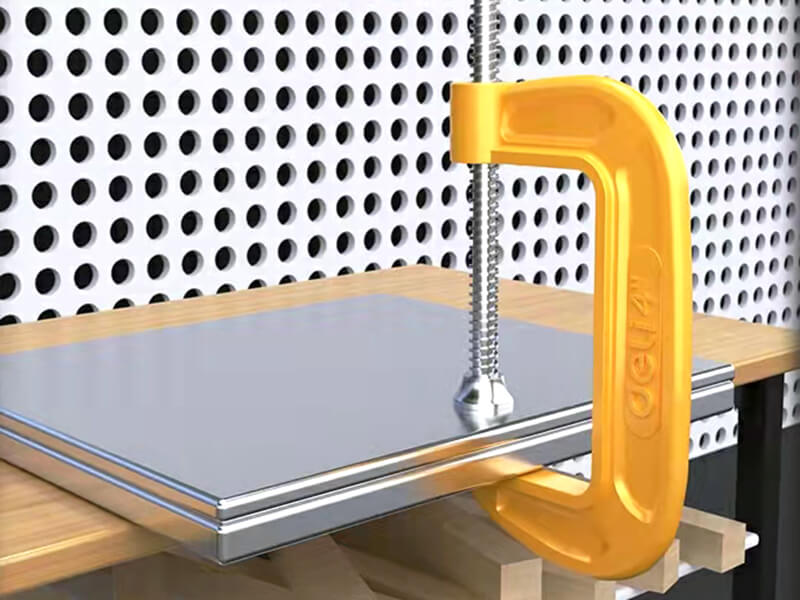

Hand saw is a suitable tool for individuals to cut polycarbonate sheets from 1.5mm 12mm in thickness and polycarbonate tubes and rods from 10mm to 150mm in diameter. This method is only for imprecise polycarbonate parts in straight line and flat applications, and in small amounts. After cutting, you need to handly the angel corner. Please check the following steps:

1. Make all tools ready

| Suitable product | Advantage | Disadvantaged |

|---|---|---|

| Polycarbonate sheet from 1.5mm to 15mm, polycarbonate rod and tube from 5mm to 100mm | 1. Suitable for individuals; 2. Suitable for small amounts; 3. Suitable for polycarbonate sheet, rod, tube | 1. Only for straight-line cutting; 2. Low machining precision; 3. Not suitable for long cutting; |

Cutting Polycarbonate by Knife

If you just want to cut a thin polycarbonate sheet from 0.125mm to 1mm in a straight line, and the quantity is not big, the knife will be a good choice. It is really a method of cutting polycarbonate, but it is not suitable to cut large polycarbonate, thick polycarbonate sheets, or polycarbonate rod/tube.

| Suitable product | Advantage | Disadvantaged |

|---|---|---|

| Polycarbonate sheet from 0.125mm to 1mm | 1. Suitable for thin polycarbonate sheet; 2. Suitable for one or two pieces; 3. Easy to operate; | 1. Only for straight-line cutting; 2. Low machining precision; 3. Not suitable for long cutting; |

Cutting Polycarbonate Table Saw

Table saw is also a popular tool to cut polycarbonate sheets, rods/tubes in factories or project sites. It is only to cut a large sheet into small pieces or cut some polycarbonate roofing sheet because it is high-effective, and tolerance is about ±2mm.

| Suitable product | Advantage | Disadvantaged |

|---|---|---|

| Polycarbonate sheet from 1mm to 12mm in thickness, polycarbonate rod/tube from 3mm to 20mm in diameter | 1. Suitable for polycarbonate sheet, rod, tube; 2. Suitable for mass production; 3. Easy to operate; 4. Can cut to angle; | 1. Only for straight-line cutting; 2. Low machining precision; |

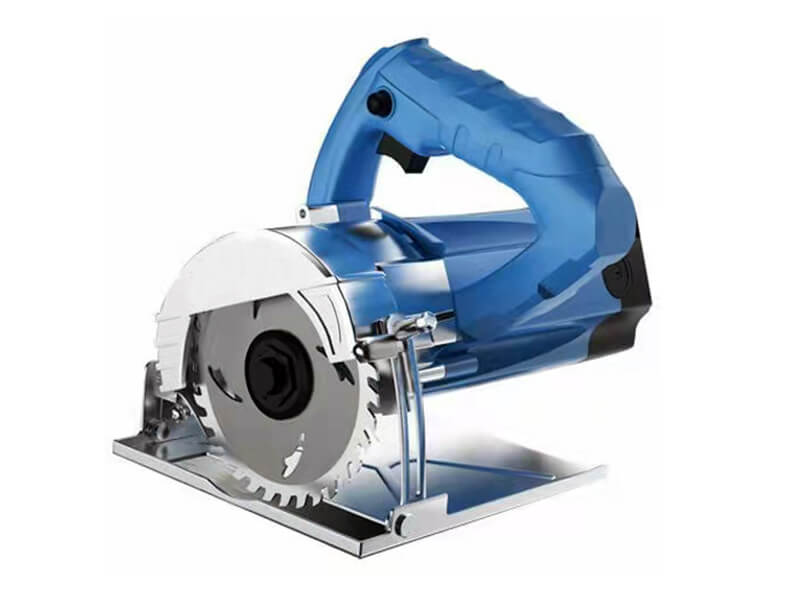

Cutting Polycarbonate Circular Saw/Jigsaw

Circular Saw is suitable to cut polycarbonate roofing sheets on the project site when installing because it is portable, you can take it to your construction site and, the tolerance is not good. Otherwise, it is suitable to cut polycarbonate rods from 15mm to 40mm.

| Suitable Product | Advantage | Disadvantaged |

|---|---|---|

| Polycarbonate sheet from 3mm to 12mm in thickness, polycarbonate rod from 3mm to 15mm in diameter | 1. Suitable for polycarbonate sheet, rod, tube; 2. Suitable for mass production; 3. Easy to operate; 4. Can cut to angle; 5. Portable cutting tool; 6. Cutting line can be straight and arc. | Low machining precision; |

Cutting polycarbonate by scissor

Yes, scissors can cut polycarbonate. It only cut very thin polycarbonate sheets, like 0.125mm, 0.25mm in thickness, and simple shape. It is not a popular cutting method.

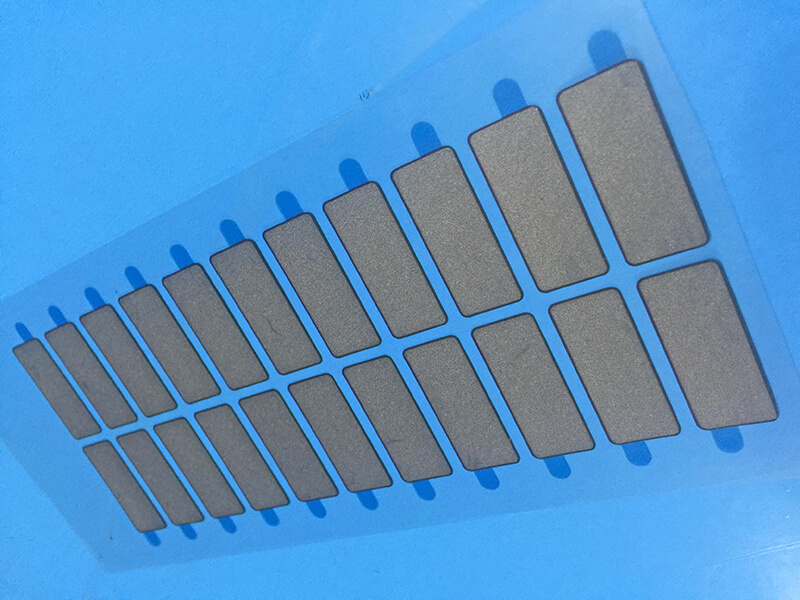

Die-cutting Polycarbonate

Die-cutting polycarbonate is the most efficient method, it is the best method for large quantity production because you need to pay for the mold, which is made of steel.

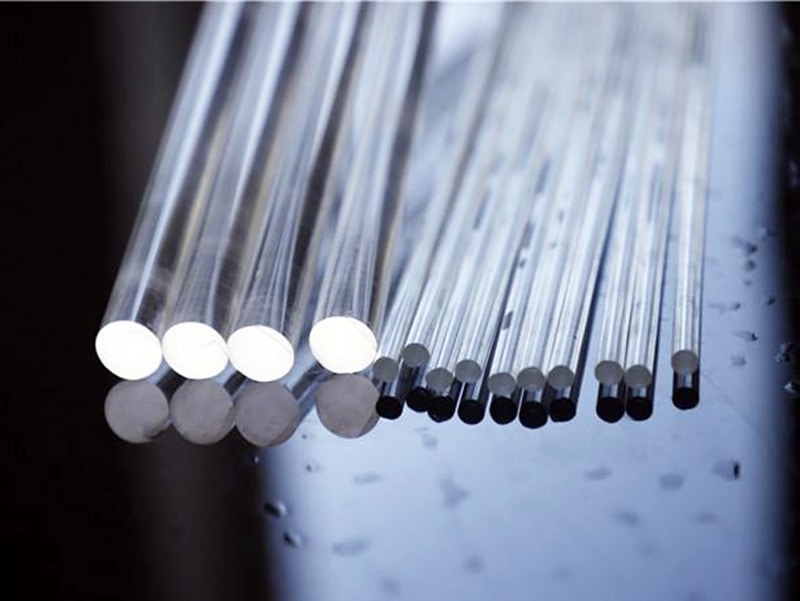

How to cut polycarbonate rod/tube?

Yes, polycarbonate material can be machined into rod/tube with diameters from 3mm to 600mm, because this material is really strong. It can be used in most industries. So how to cut a polycarbonate rod/tube? Normally, we are using the following methods:

Cutting polycarbonate rod/tube by saw

A saw is a tool to cut polycarbonate rods for imprecise parts. And when you need to cut a long polycarbonate rod to shart one, it is also a good method. Frequently-used saws are bench saw, hand saw, circular saw, etc.

Cutting polycarbonate rod/tube by horizontal lathe

A horizontal Lathe is the best tool to machine polycarbonate rod/tube. It can cut any plastic rods/tubes precisely and can tap them.

Frequently Asked Questions

Can I cut polycarbonate by laser cutting machine?

No, the laser cutting machine can’t be used to cut polycarbonate material, it will make the cutting surface yellow.

What is the best blade for cutting polycarbonate?

You can use a bench saw for a straight line cutting polycarbonate, and use the jigsaw to cut polycarbonate in arc or circle. And the CNC Router will be suitable for all shapes.

How do you cut polycarbonate by hand?

Yes, you can cut polycarbonate with a thickness of 3mm by hand. For thicker polycarbonate, it will be better to cut it with a saw or CNC router.

What do I need to do after cutting polycarbonate?

Yes, you need to clean the side after cutting polycarbonate.

Conclusion

Cutting polycarbonate is one of the machining methods for polycarbonate. If you are looking for a supplier of cutting polycarbonate, UVPLASTIC will be a trustworthy one.

UVPLASTIC is one of the leading manufacturers of polycarbonate in China, meantime, we provide machining services. Today, we are providing machining services to more than 2000 clients from more than 40 countries.