Molding Polycarbonate, You Need To Know

Printing Plastic

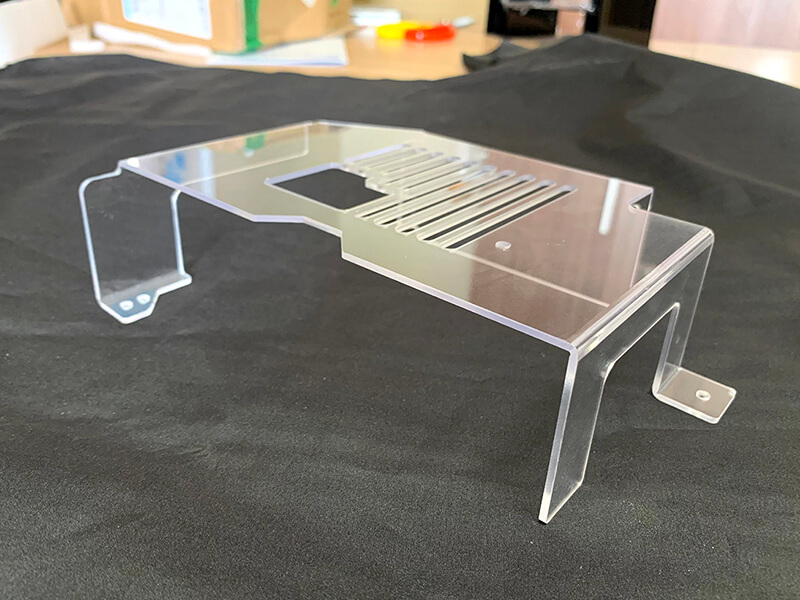

Bending Polycarbonate

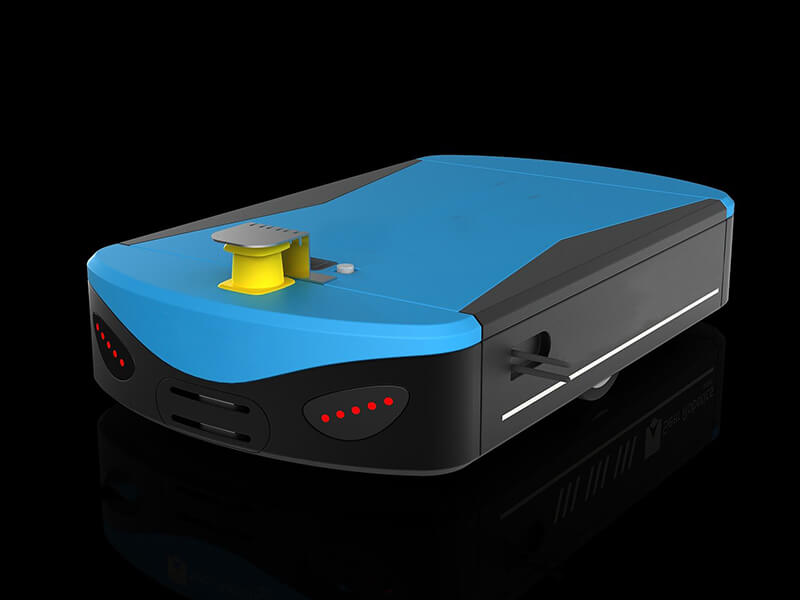

Molding polycarbonate is a popular process to machine polycarbonate material to polycarbonate parts with a special shape or size by thermal forming. These polycarbonate parts are used frequently in architecture, agriculture, automation, robot, AGV, medical devices, recreation equipment, aviation, aerospace, pinball machine, eyeglass lenses, equipment housings, etc. Today, we will discuss all information about molding polycarbonate.

Polycarbonate Material

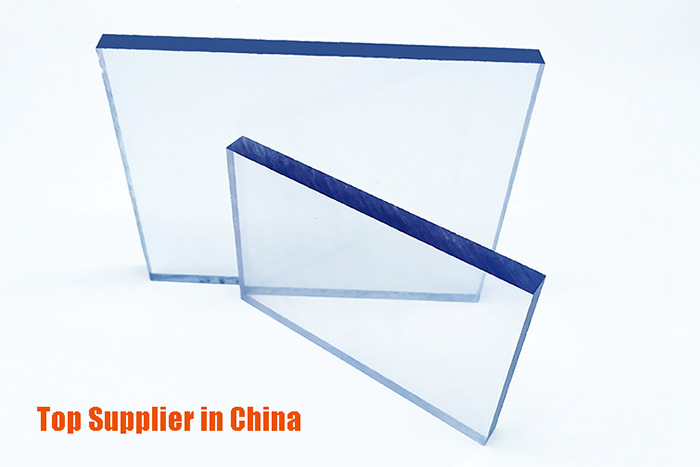

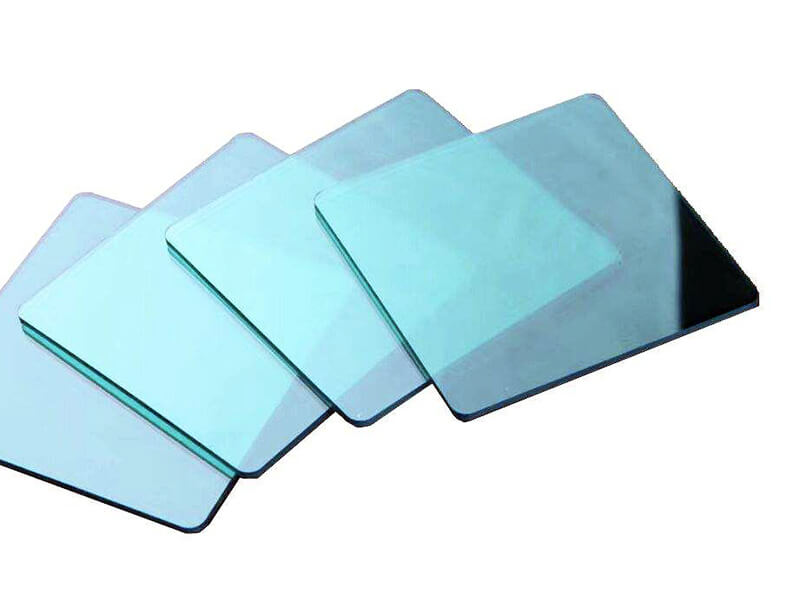

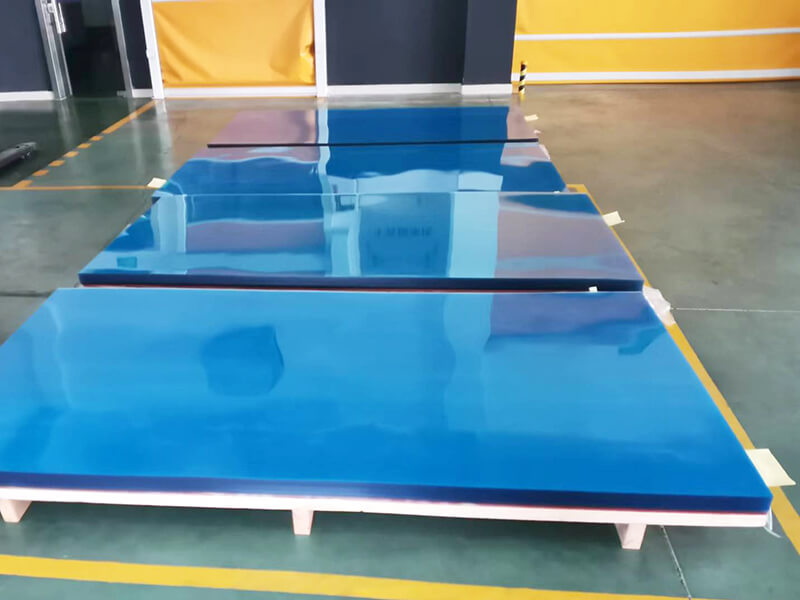

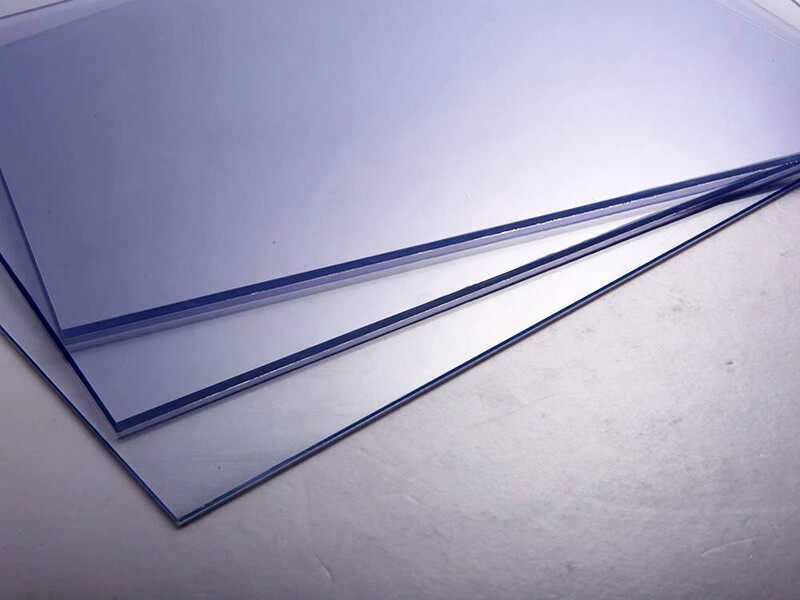

Polycarbonate material is a strong thermoplastic polymer, normally, it is white power, and transparent granular. The molecular structure of these materials provides high stiffness, good thermal resistance, and relatively high viscosity during processing. In the market, it is easy to find polycarbonate materials in the following forms:

| Item | Specification | Color description |

|---|---|---|

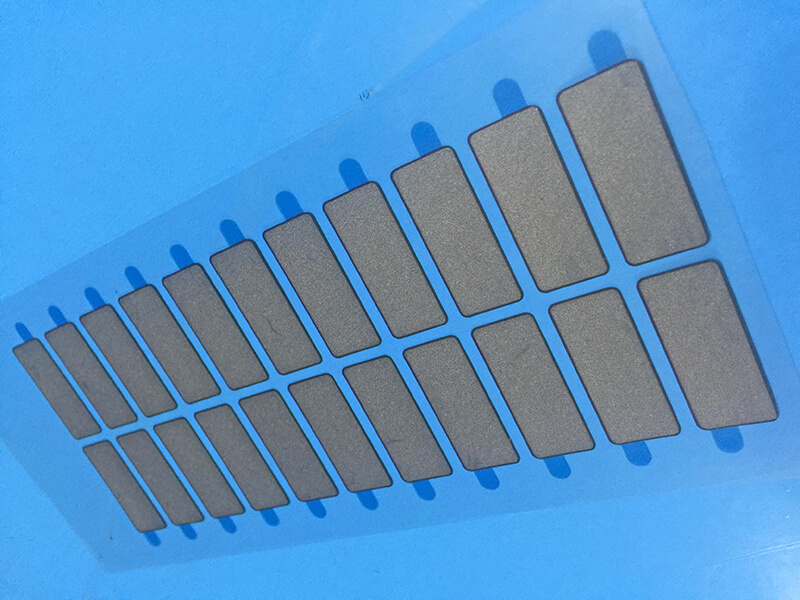

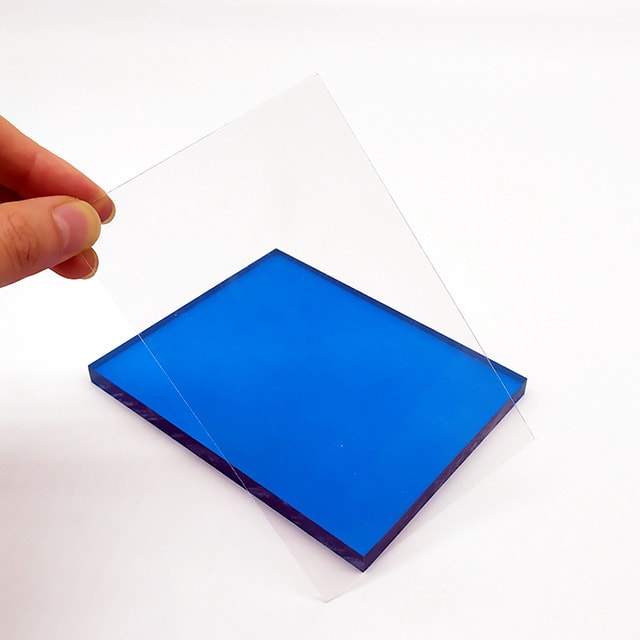

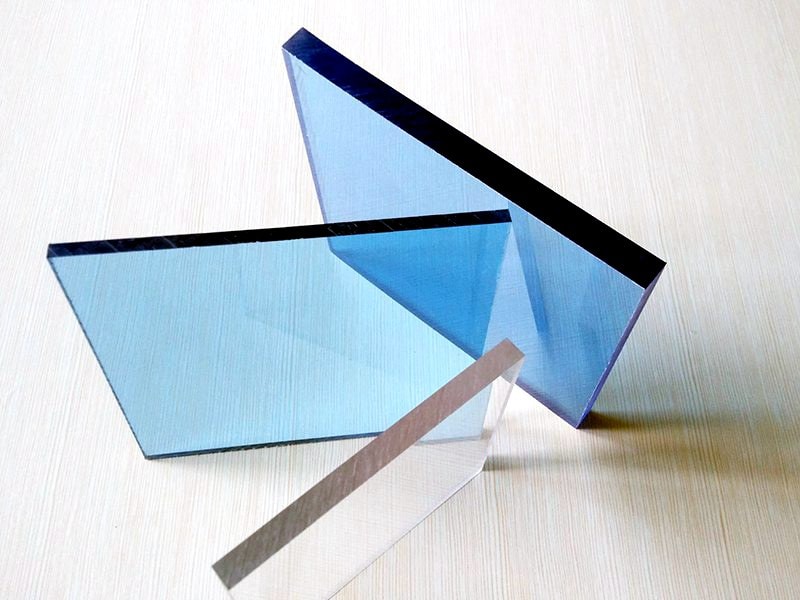

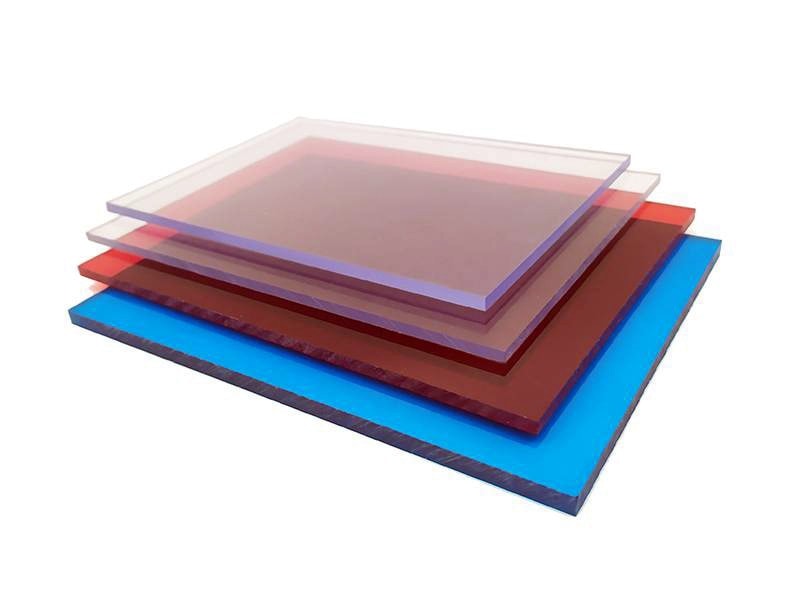

| Polycarbonate sheets | Thickness: from 0.8mm to 20mm; Max. Width: 2.7 meters; Length can be customized; | Transparent, brown, grey, blue, green, and custom colors. |

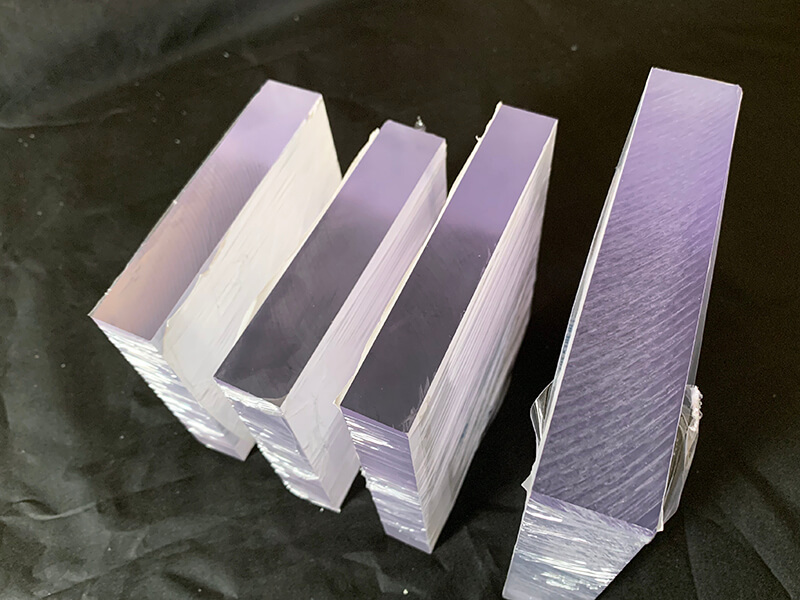

| Polycarbonate block | Thickness: from 20mm to 40mm; Size: 1220×2440 mm; | Transparent and custom colors. |

| Polycarbonate rod | Diameter is from 12mm to 120mm; Custom diameter; | Transparent and custom colors. |

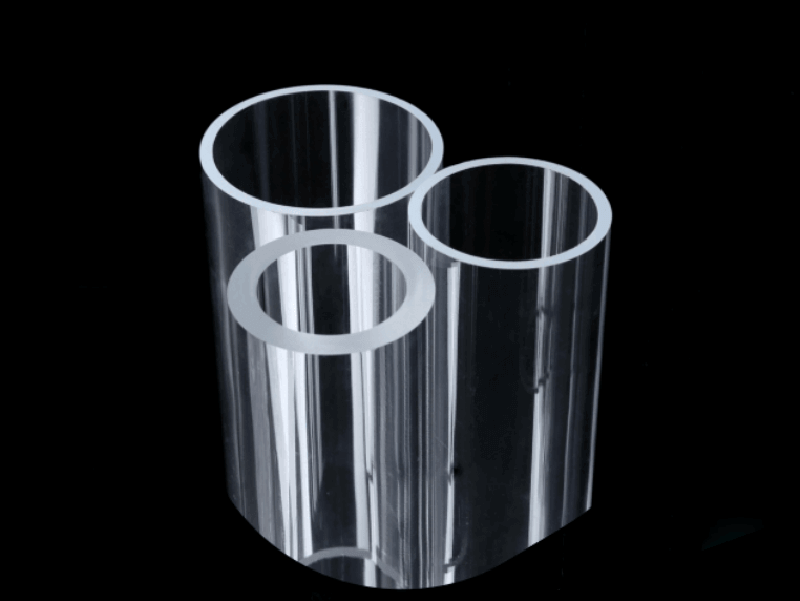

| Polycarbonate tube | Diameter is from 50mm to 75mm; Thickness is from 1mm to 5mm; Custom diameter and thickness; | Transparent and custom colors. |

| Polycarbonate film | Thickness is from 0.125mm to 0.75mm; Size: 1220×2440 mm; | Transparent and custom colors. |

The methods of Molding Polycarbonate

Vacuum Forming polycarbonate

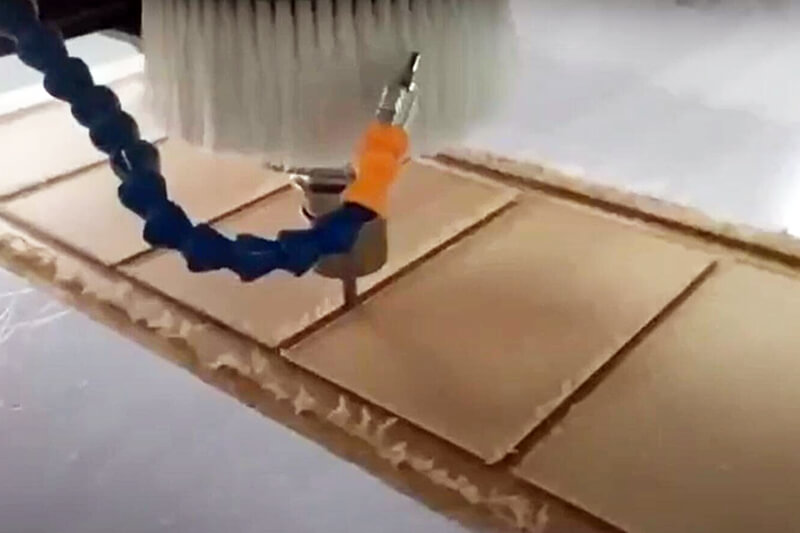

Vacuum forming is a simple method of thermoforming plastic sheets, such as polycarbonate sheets/film, ABS sheets, plexiglass sheets, PET sheets, etc.

The process of vacuum forming:

What plastic sheets are suitable for the vacuum forming process?

What products can be manufactured by the vacuum forming process?

The vacuum forming process is used for most products in almost many industries, it is friendly for any quantities, UVPLASTIC is a professional supplier of vacuum forming plastic for most industries, please check the following list for some parts in different industries.

| Industry | Products | Material |

|---|---|---|

| Automative | Door, window, skylight, engine hood, door interior, storage box, etc. for refitted vehicles and recreational vehicles; | Polycarbonate, ABS |

| Material handling | Shipping trays/pallets; Storage containers; | Polycarbonate, ABS |

| Drone | Drone housing | Polycarbonate, ABS |

| Automation | Cover of AGV; Cover of automation equipment; | ABS, PETG; |

| Medical device | Equipment covers; Large equipment panels; Packaging for pharmaceuticals and sterile equipment; Medical trays and stands; | ABS, PETG, PC; |

| Telecommunications | Equipment panels; Exterior cases for computers; | PVC, Polycarbonate, ABS |

| Transportation | Plastic table; Seat for subway train; | ABS |

| Architecture | Skylight dome | Polycarbonate |

| Agriculture | Hydroponic plant tray | PVC, Polycarbonate |

Pressure forming polycarbonate

Pressure forming is one of the thermal forming plastic methods by using pressure on the plastic sheet to create a special shape. This process works in the opposite way to vacuum forming. Instead of removing the air between the plastic and the mold, pressure forming uses air pressure to push the plastic sheets down on the mold.

Pressure forming can use more than triple the amount of air pressure than vacuum forming, therefore, the edges of the product are high-quality. By using pressured air, the heat can be transferred to the plastic sheet quickly and can reduce the time of the thermoforming process, and it is efficient.

Pressure forming is a good process to replace metal sheets, fiberglass, and wood component. It is also an ideal method for large parts.

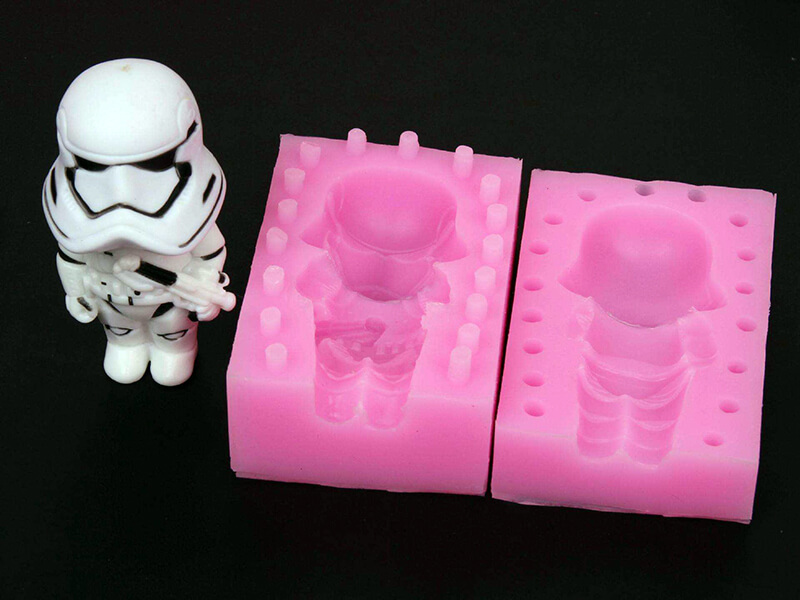

Vacuum Casting polycarbonate

Vacuum casting is a good process for creat middle parts in small quantities by using liquid plastic material and silicone mold. It is a very efficient, economical method to create plastic parts.

How does the vacuum casting process work?

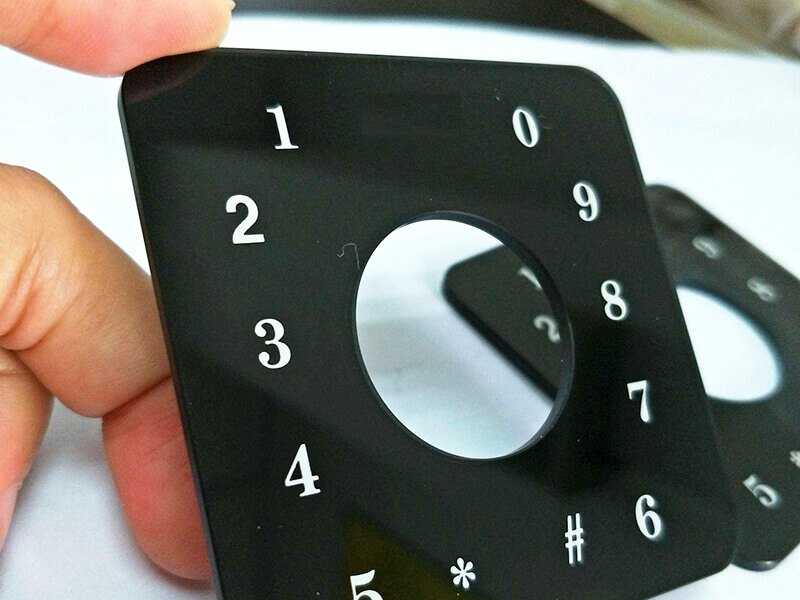

Polycarbonate injection molding

Polycarbonate injection molding is the best process to manufacture polycarbonate parts in large quantities, it is a naturally transparent amorphous thermoplastic that is used to manufacture a wide range of materials that require advanced impact resistance and translucent qualities.

What products can be manufactured by the polycarbonate injection process?

Conclusion

Molding polycarbonate is a very important process to make plastic parts in most industries. It is also suitable for low-volume manufacturing. If you are looking for a trustworthy supplier for your molding polycarbonate parts, UVPLASTIC will be a good choice.